Our Technology

Innovation at Every Step —

From Feedstock to Final Powder

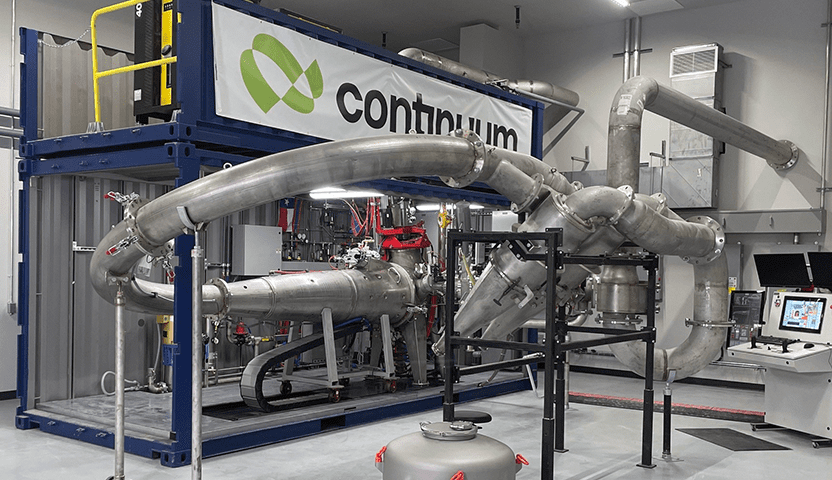

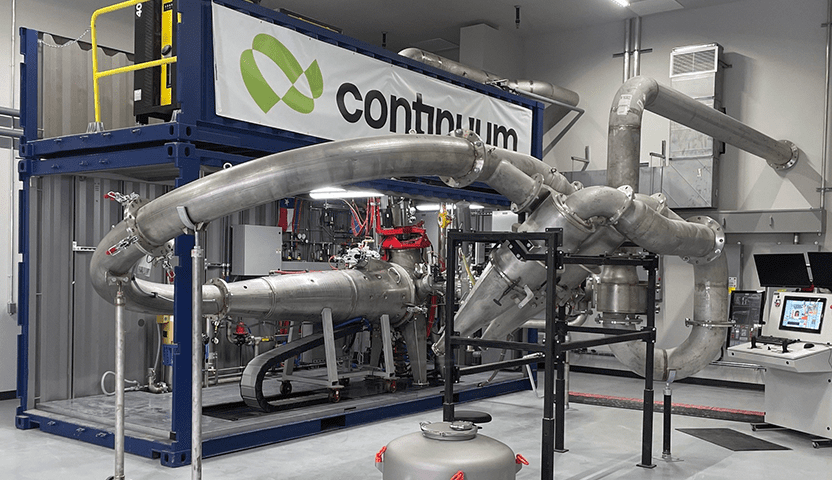

Greyhound Melt to Powder Platform

The Greyhound M2P System: Advanced Powder Reclamation Technology

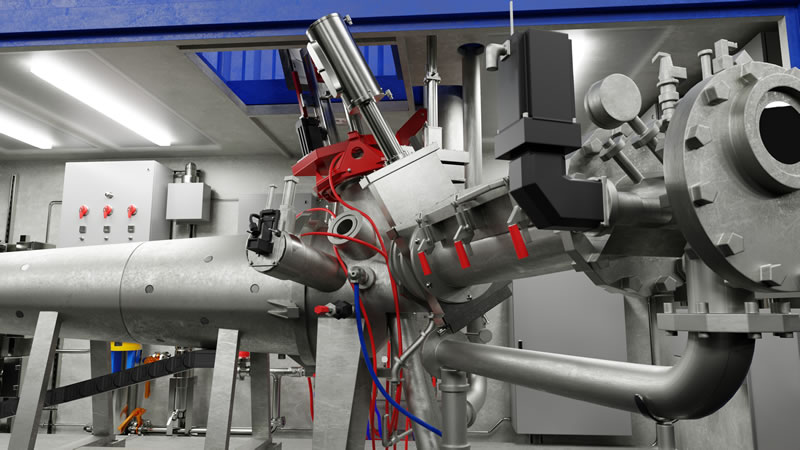

The Greyhound M2P system is Continuum Powders’ state-of-the-art solution for reclaiming and reprocessing metal feedstock into high-quality powder in a single step. Utilizing a DC plasma heat source, the Greyhound M2P system ensures efficient atomization, producing metal powders with uniform particle size, spherical shape, and exceptional flowability—ideal for advanced manufacturing processes.

Explore the Greyhound M2P System Like Never Before

This fully interactive 3D model lets you zoom, rotate, and take a closer look at the technology powering our melt-to-powder process. See how Continuum is redefining powder production—take it for a spin and discover the future of sustainable, high-performance alloys.

Full-Service Powder Management

Certified Powder Supply (ASTM-Grade, Ready for Production)

Get the exact powder you need—on spec, on time, with full traceability. Continuum supplies proven OptiPowder alloys and produces to-order material for your platform and program requirements, supported by documented chemistry and quality controls that drive lot-to-lot consistency.

Greyhound Melt-to-Powder (M2P) Atomization (Performance + Control)

A modern atomization platform built for demanding applications. Greyhound M2P enables tight PSD control, strong flowability, and low inclusion/oxygen outcomes—supporting critical applications across aerospace, energy, and industrial markets.

Powder Lifecycle Management (Closed-Loop Material Strategy)

Turn scrap, failed builds, and metal waste into production-ready powder. Continuum’s lifecycle model reclaims and reprocesses valuable metal assets into ASTM-grade powder in a streamlined pathway designed to reduce waste and improve material efficiency.

Alloy & PSD Customization (Built Around Your Platform)

When off-the-shelf won’t do, we engineer to your process. From custom compositions to process-specific PSD tuning, our metallurgists collaborate with your team to hit performance targets for LPBF, MBJ, DED, HIP, and beyond.

Scrap Sourcing, Preparation & Treatment (Quality Starts Upstream)

A cleaner input stream for a cleaner powder output. We build robust access to high-quality feedstock and apply preparation methods (including cleaning/etching) to protect chemistry and integrity before conversion.

Toll Atomization Services (Recover Value from Oversized/Off-Spec Material)

Convert low-value material back into high-performance feedstock. Continuum offers toll atomization to reclaim oversized/off-spec powder and return it as usable, high-performance material—reducing waste and strengthening supply chain resilience.

Metal Reclamation

Our Reclamation Process: Turning Used Material into High-Quality Powder

At Continuum Powders, we transform end-of-life metal components into premium, ASTM-grade powders through our advanced reclamation process. By converting previously used materials back into high-performance powders, we support a circular economy that reduces waste and minimizes the environmental footprint of manufacturing.

How It Works

Material Collection

We start by collecting used metal powders or end-of-life components directly from your facility, ensuring a seamless transition to the reclamation process.

Proprietary Melt-to-Powder (M2P) Technology

Green Energy & Sustainable Practices

Rigorous Quality Testing

Closed-Loop Integration

The reclaimed powder is delivered back to your facility, ready for use in new production cycles. Our closed-loop system not only extends the lifecycle materials, it also reduces the need for raw material sourcing.