OptiVantage

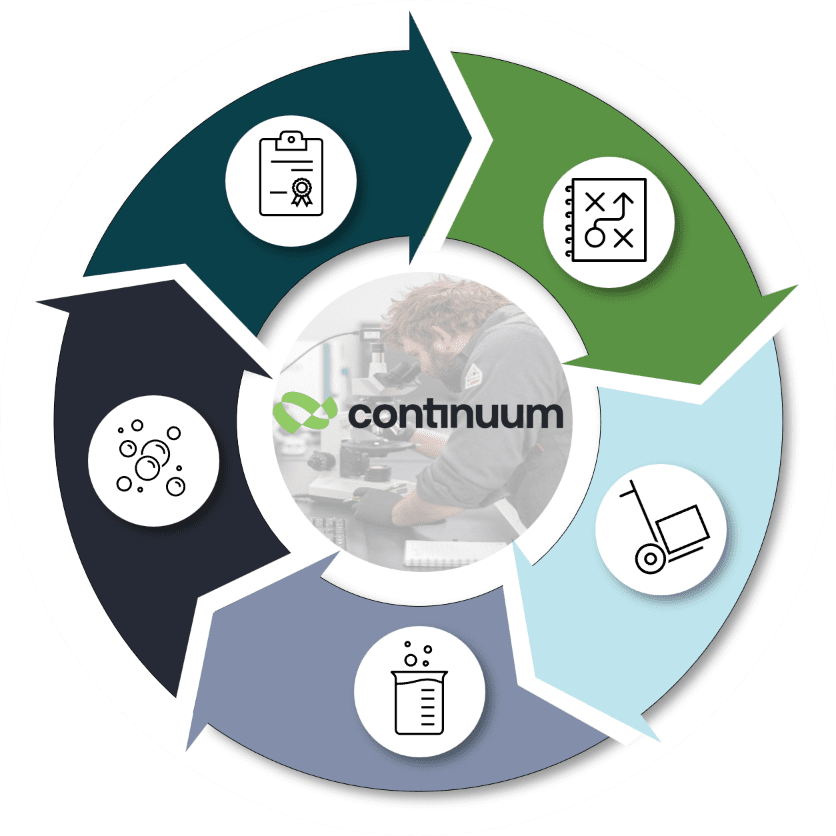

Continuum’s Quality Framework

Integrating Quality & Consistency to Transform Scrap Material into Superior Powder

OptiVantage is Continuum Powders’ proprietary quality assurance and control framework, designed to turn high-value scrap into premium, ASTM-grade metal powders through a series of interdependent, rigorously managed technical and operational processes. It sets the standard for consistency, reliability, and performance in sustainable powder production.

The OptiVantage Matrix: Five Pillars of Differentiation

1. Guaranteed Quality Assurance

Comprehensive, multi-step QA process covering chemical analysis, particle size distribution, and flowability for every batch.

2. End-to-End Logistics Coordination

Fully managed network ensures streamlined material collection, transportation, and delivery.

3. Strategic Scrap Sourcing

Vetted scrap partners provide a reliable supply of traceable, high-quality raw materials.

4. In-House Analytical Chemistry Labs

Onsite labs deliver real-time chemical analysis and precision control over powder composition.

5. Advanced Scrap Treatment Solutions

Pre-processing steps such as cleaning, etching, and inspection prepare scrap for conversion,

ensuring powder integrity from the start.

Why It Matters

OptiVantage provides the assurance manufacturers need when performance and consistency are nonnegotiable. It empowers customers to achieve supply chain resilience, cost efficiency, and sustainability—without sacrificing quality.