Proven Performance:

OptiPowder Ni718 Qualified on Renishaw Metal AM Systems

A case study in consistency, strength, and sustainability

When performance matters, qualification is everything. That’s why Renishaw, a global leader in metal additive manufacturing systems, put Continuum’s OptiPowder Ni718 to the test.

Through extensive evaluations on Renishaw AM printers, OptiPowder Ni718 delivered:

- Consistently high density: Relative densities above 99.75%, with optical densities exceeding 99.9%

- Exceptional mechanical strength: UTS up to 1340 MPa, yield strength averaging 988 MPa, and elongation at break of 22.3%

- Sustainability with impact: Produced using 100% recycled feedstock, cutting greenhouse gas emissions by 99.7% (OSU LCA)

- Cost efficiency: Up to 15% lower material costs compared to traditional powders

The result is a fully approved Ni718 powder that gives manufacturers reliable performance, superior quality, and a more sustainable supply chain.

Download the Case Study

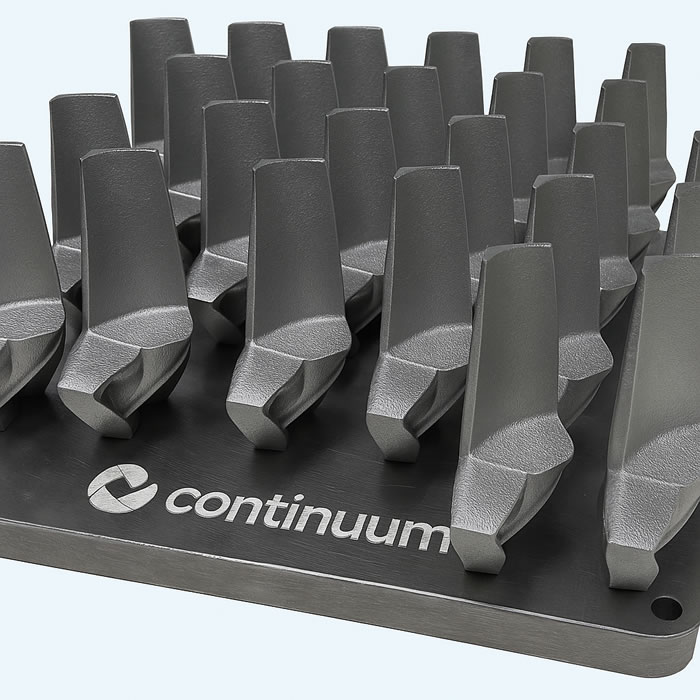

Fan Blades Printed on a Renishaw 3D Printer with Continuum’s OptiPowder Ni718