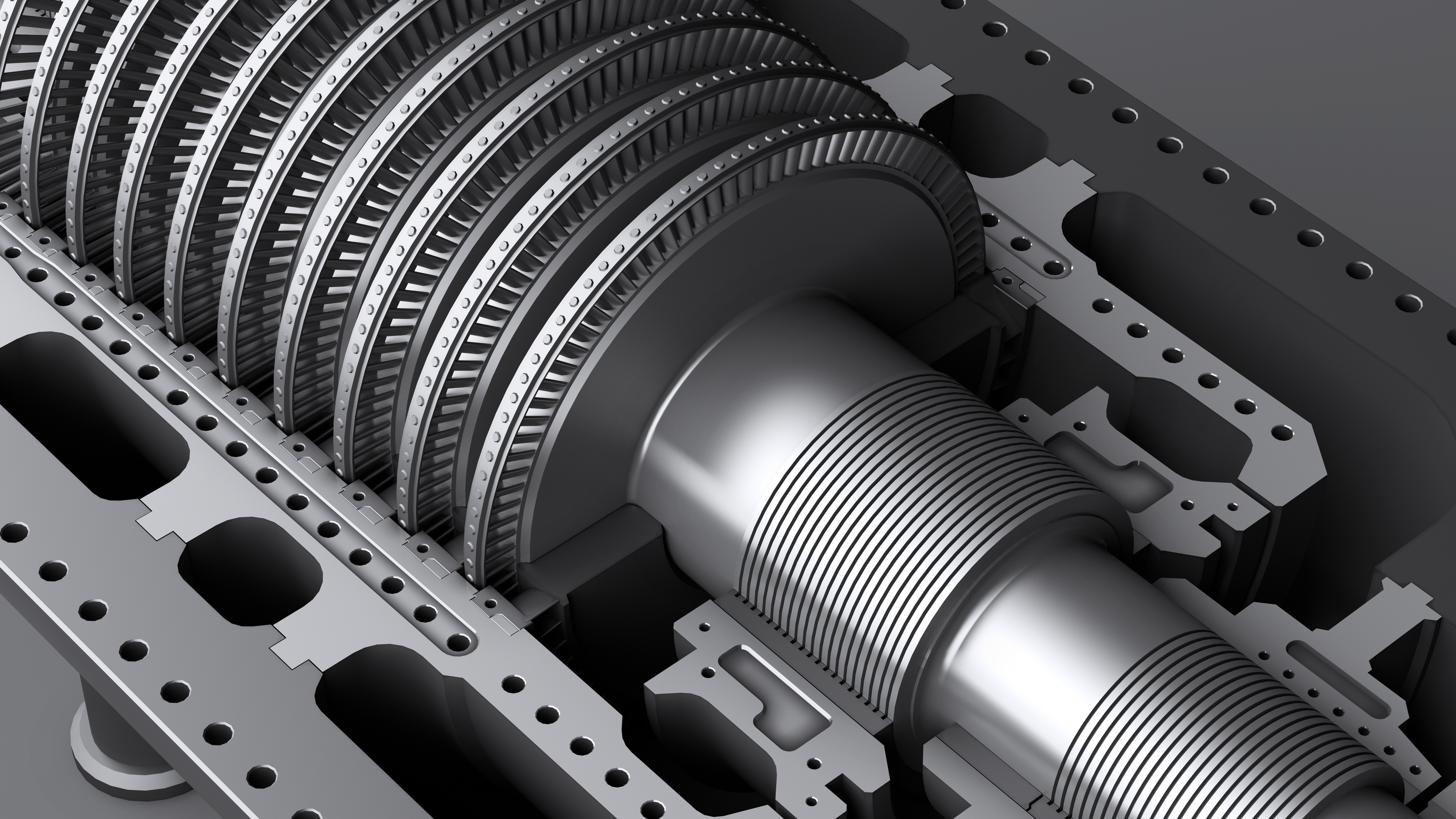

Gas turbine engines represent one of the most demanding applications for advanced manufacturing. Operating at extreme temperatures and pressures, their components require materials with exceptional strength, creep resistance, and oxidation performance. Traditionally, many of these parts have been manufactured through investment casting—a process well-suited to superalloys like Mar M247 but limited in flexibility and speed.

The Limitations of Casting

Casting provides robust material properties but often involves long lead times, expensive tooling, and constraints on part complexity. For OEMs and MROs seeking to accelerate development or reduce costs, these limitations have become increasingly restrictive.

The Role of Additive Manufacturing

Additive manufacturing (AM), particularly binder jetting and laser powder bed fusion (LPBF), offers a pathway to overcome these constraints. By directly printing parts in alloys like M247, engineers can achieve near-net-shape geometries with greater design freedom, reduced lead times, and less material waste.

The challenge has historically been material availability. Many high-performance alloys optimized for casting have not been widely available as powders suitable for AM. Qualification programs are now bridging this gap, unlocking alloys like M247 for use in binder jetting and LPBF.

Continuum’s Contribution

Continuum Powders plays a pivotal role in this transition. By producing M247 and other nickel-based superalloys through its Melt-to-Powder process, Continuum provides powders tailored for AM platforms. These powders are derived from reclaimed aerospace-grade feedstock, ensuring both performance and supply assurance.

Through strict control of particle size distribution, oxygen levels, and chemical composition, Continuum ensures that its powders meet the rigorous demands of turbine engine applications. This makes it possible for OEMs and service providers to integrate AM into production without compromising material integrity.

Unlocking Next-Generation Turbine Components

With AM-ready M247, manufacturers can design and produce components such as hot-section blades, vanes, and combustor parts that were once constrained by casting processes. AM enables rapid iteration of designs, improved cooling channel architectures, and reduced overall part counts—benefits that translate directly into higher efficiency and lower operating costs for turbines.

Enabling the Next Generation of Turbines

Additive manufacturing is not replacing casting overnight, but it is steadily unlocking new possibilities for gas turbine production. The availability of high-performance powders like M247 from suppliers such as Continuum Powders is accelerating this shift, making it possible to combine the material performance of traditional superalloys with the flexibility and speed of AM.

For the aerospace and energy sectors, this convergence represents a critical step forward: turbines built faster, smarter, and with fewer supply chain vulnerabilities—all starting from the powder.