Copper-nickel alloys have long been trusted in some of the world’s most demanding operating environments. From marine systems exposed to seawater to energy infrastructure operating under thermal and mechanical stress, CuNi materials are valued for their corrosion resistance, durability, and long-term reliability.

As additive manufacturing continues to move into these same environments, material requirements have expanded beyond basic printability. Consistency, availability, and repeatable performance are now just as critical. To support those needs, Continuum Powders has expanded its alloy portfolio with the commercial availability of CuNi 70/30 powders, OptiPowder C715 and OptiPowder C964.

A resource to help teams get started

Many engineering groups want to explore custom alloys but feel unsure about how the collaboration works. To support these conversations, Continuum created an eBook titled Powder Without Limits, which outlines how we partner with customers, how to prepare for a custom alloy request, and what to expect during the development process.

Production-Ready CuNi 70/30 Powders for Additive Manufacturing

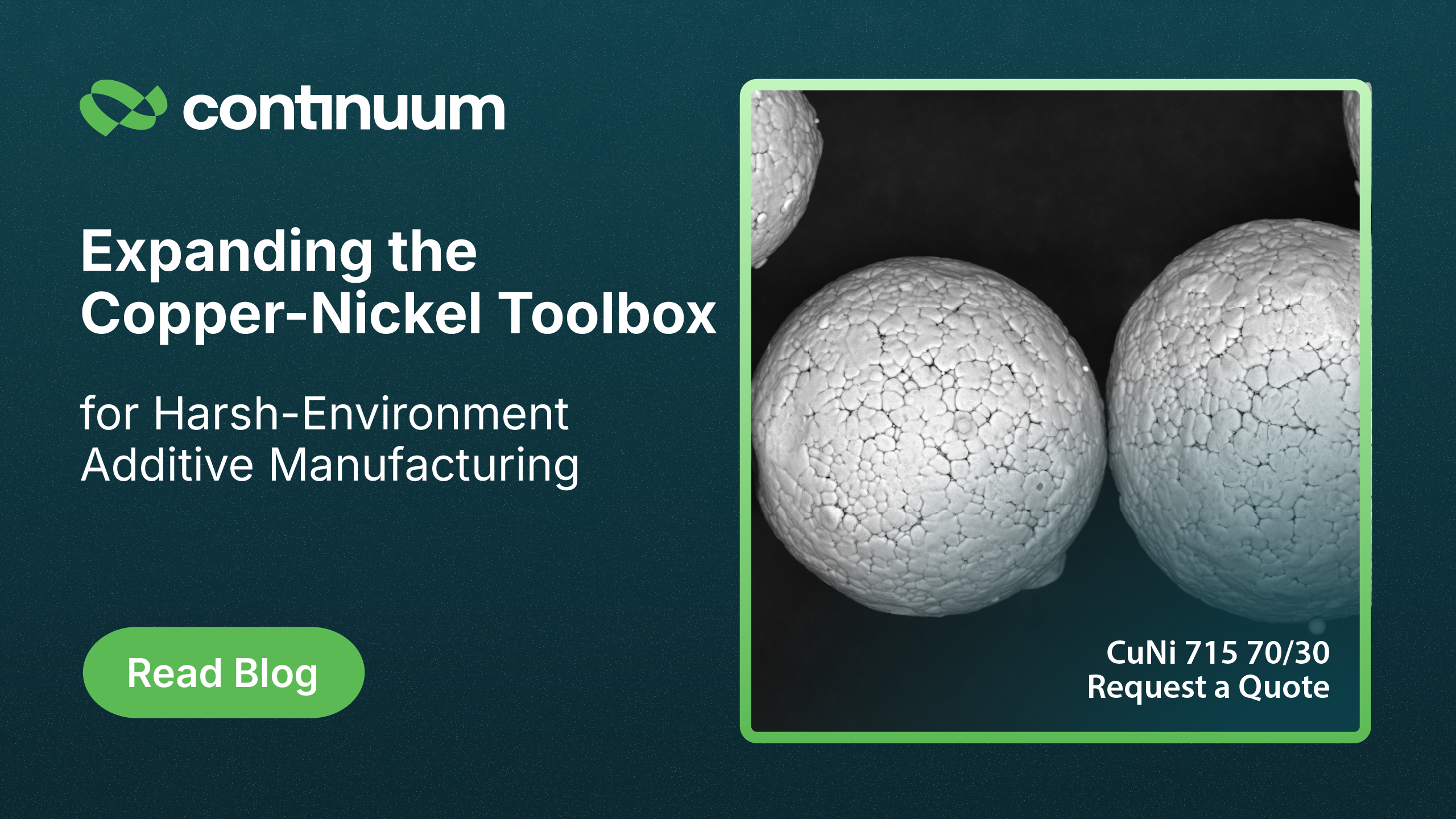

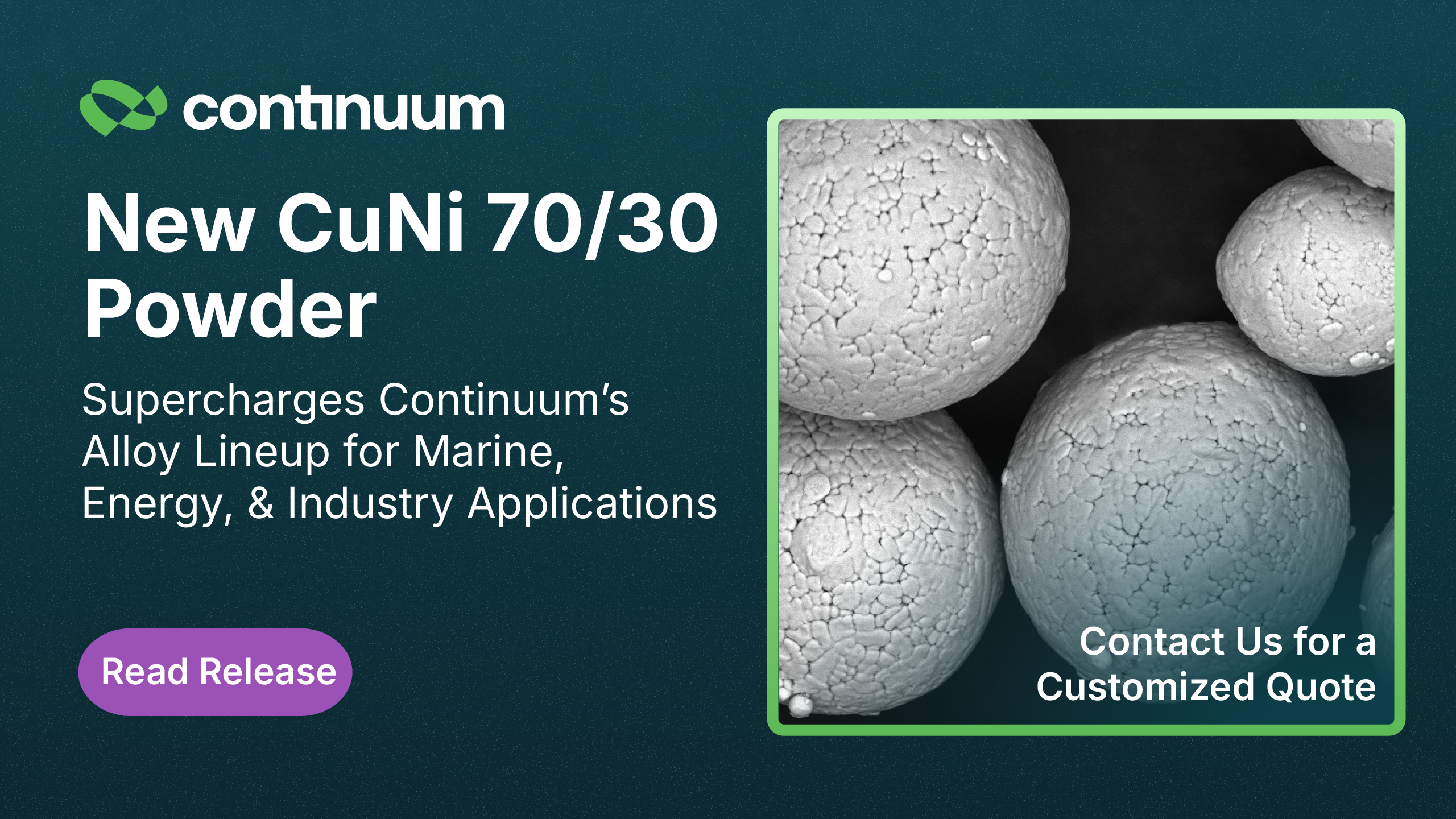

CuNi 70/30 alloys are widely used across marine, energy, and industrial applications due to their strong resistance to seawater corrosion, stress-corrosion cracking, and erosion in high-velocity environments. Translating those properties into additive manufacturing requires more than simply atomizing the alloy. Powder morphology, chemistry control, and process repeatability all play a critical role in achieving reliable results across builds and platforms.

OptiPowder C715 and C964 are produced using Continuum’s proprietary Greyhound Melt-to-Powder (M2P) atomization process. This approach transforms reclaimed, aerospace-grade scrap into high-purity, spherical metal powder engineered for consistent flowability and stable performance. Each powder is validated through Continuum’s OptiVantage quality framework, which combines analytical chemistry, physical characterization, and process controls to support repeatable outcomes in production environments.

The result is a copper-nickel powder solution designed not just for experimentation, but for sustained use in advanced manufacturing.

Copper-Nickel Performance for Marine, Energy, and Industrial Applications

The new CuNi 70/30 powders are well suited for components exposed to corrosive and high-stress operating conditions, including applications where both conductivity and durability are required. Their balanced compositions support stable mechanical behavior across a broad temperature range, making them a strong option for marine hardware, energy systems, and industrial equipment.

OptiPowder C715 and C964 are compatible with a wide range of manufacturing platforms and processes, including laser powder bed fusion (LPBF), electron beam powder bed fusion (EPBF), binder jetting, hot isostatic pressing (HIP), directed energy deposition (DED), and thermal spray. Continuum offers these alloys in multiple particle size distributions, including 10–45 µm, 15–53 µm, and 45–106 µm, with custom cuts available to align with specific machine and process requirements.

OptiPowder C715 and C964 are compatible with a wide range of manufacturing platforms and processes, including laser powder bed fusion (LPBF), electron beam powder bed fusion (EPBF), binder jetting, hot isostatic pressing (HIP), directed energy deposition (DED), and thermal spray. Continuum offers these alloys in multiple particle size distributions, including 10–45 µm, 15–53 µm, and 45–106 µm, with custom cuts available to align with specific machine and process requirements.

Reclaimed CuNi Metal Powders Without Compromising Performance

Beyond performance, the introduction of CuNi 70/30 powders reflects Continuum’s broader approach to materials development. By manufacturing powders from reclaimed feedstock, the company helps manufacturers reduce material waste while strengthening supply chain resilience and improving environmental outcomes.

This reclaimed-first strategy does not come at the expense of quality. Strict analytical controls ensure chemistry integrity and consistency, allowing customers to adopt reclaimed copper-nickel powders with confidence in both performance and repeatability. For manufacturers navigating volatile raw material markets or seeking more responsible sourcing options, this approach offers a practical path forward.

Expanding Continuum’s Alloy Portfolio for Advanced Manufacturing

The launch of OptiPowder C715 and C964 builds on a year of customer-driven progress at Continuum Powders. Through collaborations with partners such as AmPd Labs, INDO-MIM, HP, and Tecnalia, the company has demonstrated that reclaimed materials can meet the demands of production-scale additive manufacturing for high-temperature and mission-critical applications.

These new copper-nickel powders also complement Continuum’s ongoing process innovations, including its Direct Powder Feeder™, which enables unused powder to be reclaimed and returned directly to atomization for reuse. Together, these advancements support a more circular and resilient metal supply chain for advanced manufacturing.

Exploring CuNi 70/30 Powders for Your Additive Manufacturing Application

As additive manufacturing adoption continues to grow across marine, energy, and industrial sectors, interest is increasing in corrosion-resistant and high-conductivity CuNi 70/30 metal powders that can support reliable production.

For teams evaluating copper-nickel alloys for metal additive manufacturing, OptiPowder C715 and C964 offer a production-ready option grounded in proven alloy performance and modern powder engineering. If you are exploring CuNi materials for LPBF, binder jetting, HIP, DED, or thermal spray applications, we encourage you to connect with our materials team to discuss requirements, powder sizing, and qualification considerations.