Cradle-to-gate study shows recycled nickel can deliver 58.8%–98.7% lower global warming potential than virgin-based powder production

HOUSTON, TX February 18, 2026 — Continuum Powders today announced the results of an independent Life Cycle Assessment (LCA) conducted by Oregon State University’s Industrial Sustainability Laboratory, quantifying the global warming potential (GWP) of nickel (Ni) powder production used in additive manufacturing.

The cradle-to-gate study compares a conventional, virgin-material gas atomization pathway with recycled-material production routes enabled by Continuum Powders’ plasma arc atomization technology.

Oregon State University Ph.D. Student David Okenwa with Professor Karl Haapala putting the final changes on the assessment

Across multiple modeled scenarios, the analysis demonstrates that using recycled nickel feedstock can deliver substantial, measurable reductions in greenhouse gas (GHG) emissions—without altering the fundamental requirements of production-grade powder manufacturing.

Recycled feedstock delivers meaningful GWP reductions

The assessment was conducted as an independent, cradle-to-gate life cycle assessment by Oregon State University’s Industrial Sustainability Laboratory, using established LCA methodology to evaluate material sourcing, energy use, and process emissions associated with nickel powder production.

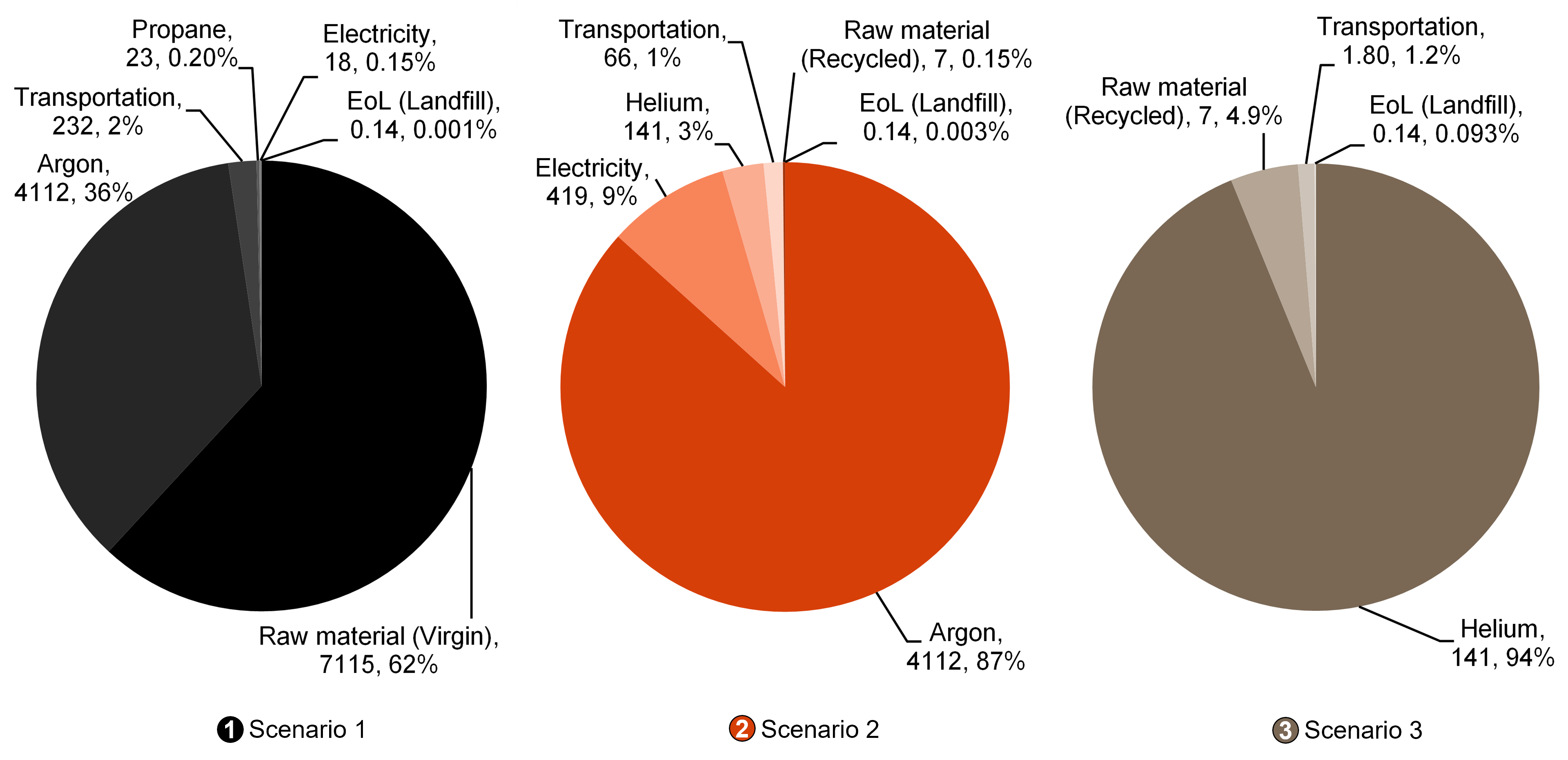

Researchers modeled three production scenarios to assess relative environmental impacts:

- Scenario 1 (baseline): Conventional gas atomization using 100% virgin nickel

- Scenario 2: Plasma arc atomization using recycled nickel feedstock (modeled as 70% internal / 30% external). Internally recycled material is comprised of unatomized nickel from the previous powder production cycles at the facility, while externally recycled material is purchased from suppliers across Canada and the USA.

- Scenario 3: Plasma arc atomization using recycled nickel combined with additional sustainability levers, including carbon offsets for electricity and argon consumption. Externally recycled nickel is also sourced locally.

Drivers of GWP for Scenario 1 (Left), Scenario 2 (Middle) and Scenario 3 Which Models Continuum’s Houston Facility Process.

Compared to the baseline scenario, the study found that GWP was 58.8% lower in Scenario 2 and 98.7% lower in Scenario 3, highlighting the significant GHG reduction potential of recycled nickel and environmentally conscious purchasing pathways.

The analysis identified argon and electricity as the dominant contributors to remaining emissions in recycled-material scenarios—accounting for approximately 87% and 9% of GWP impacts, respectively, in Scenario 2. The report notes that sourcing lower-carbon argon and electricity is a primary driver behind the dramatic footprint reductions modeled in Scenario 3.

Implications for additive manufacturing supply chains

Nickel powder is a critical feedstock for demanding additive manufacturing applications across aerospace, automotive, energy, and industrial sectors. At the same time, sustainability expectations are increasing across both commercial and defense manufacturing ecosystems.

The Oregon State LCA provides independent, quantitative evidence that recycled nickel inputs—when paired with cleaner utilities and optimized sourcing strategies—can materially reduce the environmental footprint of powder production while supporting scalable, qualification-ready additive manufacturing supply chains.

This assessment shows that transitioning from virgin nickel to recycled feedstock can significantly reduce the global warming potential associated with nickel powder production. This is facilitated by using plasma arc atomization instead of conventional gas atomization. The greatest reductions occur when recycled inputs are paired with lower-carbon electricity and inert gas sourcing.

Manufacturers are increasingly looking for sustainability outcomes that are measurable—not aspirational. This study helps quantify the impact of reclaimed feedstock and reinforces why we’ve invested in production-grade powder platforms designed to reduce emissions without compromising quality or performance.

About Continuum Powders

Continuum Powders produces reclaimed, premium metal powders using proprietary Melt-to-Powder technology that transforms certified metal revert streams into high-quality spherical powder. The company supports additive and advanced manufacturing applications with process-ready materials, custom particle size distributions, and alloy development programs built for qualification and scale.

Media Contacts

Marketing Communications Director, Continuum Powders

Professor – Industrial Sustainability Laboratory, School of Mechanical, Industrial, and Manufacturing Engineering, Oregon State University