What Really Happens to Aerospace, Defense & Energy Scrap?

Titanium and nickel superalloys are essential to modern manufacturing. Known for their strength, low weight, and resistance to extreme conditions, they’re the go-to materials for aerospace, defense, and energy parts. But once these materials become machining scrap—what then?

Too often, high-value titanium turnings and nickel alloy byproducts are downgraded to low-grade scrap or discarded altogether. That’s not just wasteful, it’s a missed opportunity. Valuable materials end up in landfills or get exported, creating unnecessary environmental impact and increasing supply chain risk.

Titanium & Nickel: The Status Quo Isn’t Working

The typical path for scrap is simple: collect, sell, and ship to scrap dealers. But titanium and nickel turnings are often contaminated with coolants, oils, and lubricants. That makes it harder to recycle and requires complex, energy-intensive cleaning before they’re even usable again.

Traditional recycling methods for titanium, such as remelting and refining, are highly energy intensive. For instance, the U.S. Department of Energy reports that producing titanium through conventional means can consume up to 39,000 kWh per ton, making it one of the most energy-demanding metals to process. As a result, prime aerospace-grade scrap often gets downcycled into low-spec applications.

In many cases, it doesn’t get recycled at all. Instead, it’s landfilled or exported, removing critical materials from domestic supply chains and driving up long-term costs and risks. Exporting high-grade scrap materials undermines domestic supply chain resilience. In fact, the DoE emphasizes the importance of retaining critical minerals like titanium and nickel to support national security and economic competitiveness.

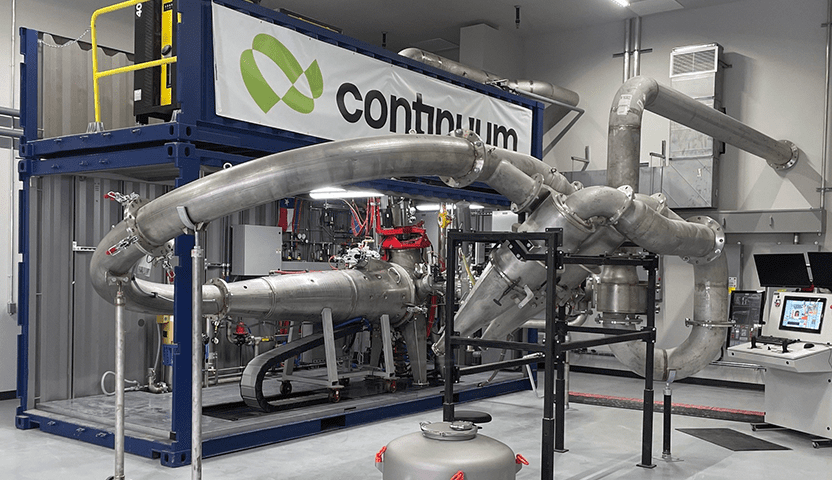

Continuum Greyhound Melt-to-Powder Foundry

Leveraging advanced gas atomization, our patented process ensures cost-effective, sustainable production with traceable, certified quality.

Time to Rethink the Recycling Playbook

Landfilling or exporting aerospace-grade scrap isn’t just inefficient, it’s a strategic loss. These materials could and should stay in the manufacturing ecosystem, feeding back into aerospace, defense, and energy programs that demand peak performance.

Continuum Powders CEO Rob Higby recently told 3DPrint.com that global supply chains are growing more complex and more fragile, especially in critical industries. Keeping control of key materials like titanium and nickel is no longer optional. It’s a necessity.

Continuum Powders: Scrap-to-Powder, Reinvented

Continuum Powders is changing how the industry thinks about scrap. Our proprietary Melt-to-Powder (M2P) technology takes aerospace- and energy-grade titanium and nickel scrap and transforms it directly into ASTM-grade metal powders, ready for additive manufacturing and other advanced production methods.

Unlike traditional recycling, our process skips the multiple remelting stages entirely. That means lower energy use, lower emissions, and lower costs—without compromising performance. In fact, a Life Cycle Assessment (LCA) of nickel powder production conducted by the Oregon State University found that Continuum Powders’ Greyhound M2P plasma atomization process cuts carbon emissions by up to 99.7% compared to traditional virgin nickel powder production.

In fact, our process preserves and even improves powder quality and consistency. The result is a high-purity, high-performance powder that meets the stringent demands of aerospace, defense, and energy applications.

Why It Matters for Critical Industries

By adopting Continuum’s Scrap-to-Powder model, manufacturers can:

- Shrink their environmental impact while meeting tough ESG requirements

- Strengthen supply chains by turning scrap into usable feedstock, reducing reliance on imports and virgin materials

- Cut costs through better material efficiency and reduced energy input

It’s a smarter way to manage scrap—turning what used to be waste into a competitive advantage.

Charting a More Secure, Sustainable Future

There’s never been a better time to rethink how we handle high-value metal scrap. Continuum Powders offers a smarter, more strategic solution—one that helps manufacturers reduce waste, cut emissions, and secure their supply chains from the ground up.

Want to see how our Scrap-to-Powder model can fit into your operations? Visit continuumpowders.com or click below to get in touch with our team. We’d love to talk.