The metal manufacturing industry has long faced a fundamental tension: how do you scale production of high-performance metals while also meeting the increasing global demand for sustainability? Historically, the answer has often been you can’t. Traditional metal production relies heavily on mining, energy-intensive refining processes, complex global logistics, and wasteful scrap practices—all of which come with significant environmental costs. But at Continuum Powders, we believe that sustainable metal manufacturing isn’t just a distant goal — it’s entirely achievable right now. The key is to rethink the process from the ground up.

For decades, sustainability in metal manufacturing has been treated more like an offset equation than a process redesign. Companies have focused on incremental gains—improving mining efficiency, recycling certain scrap streams, or investing in carbon offsets. While these steps are important, they fail to address the root problem: conventional methods of producing metal powders remain inherently resource-heavy and emission-intensive. The primary driver of this impact lies in the front end of the supply chain — mining virgin ore, refining it through multiple complex steps, and shipping raw materials globally before they even reach a powder producer.

Continuum Powders takes a different approach. Our business is built on the belief that the highest-performing metal powders don’t require a single ounce of freshly mined material. Instead, we use certified, aerospace- and energy-grade scrap metal as our primary feedstock, directly converting it into high-performance powder suitable for even the most demanding applications. This isn’t simply recycling in the traditional sense. We apply a highly controlled, technically rigorous process to transform previously used metal components into fully certified, application-ready powders that meet or exceed the specifications of powders produced from virgin raw materials.

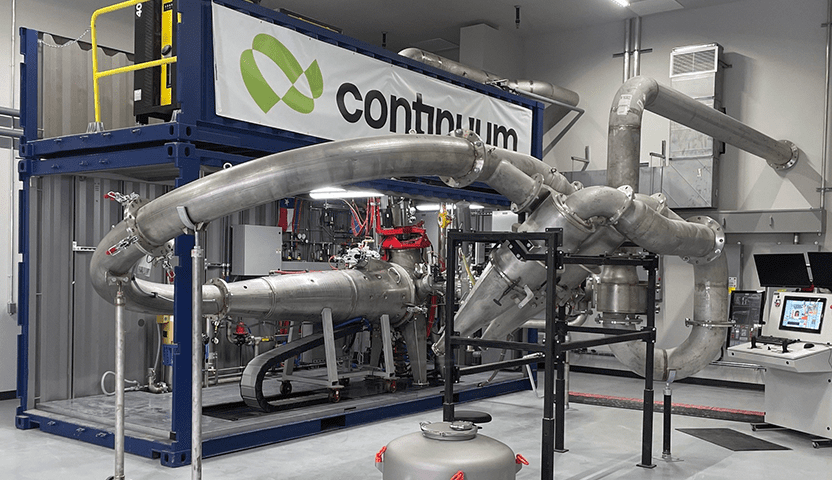

At the heart of our process is Continuum’s Greyhound Melt-to-Powder (M2P) system. Unlike conventional metal powder production, which often requires multiple remelting and refining steps that degrade material quality and generate substantial emissions, M2P converts scrap directly into powder in a single, tightly controlled step. This matters because every additional processing stage in traditional recycling not only adds cost, but also introduces potential variability in chemistry, microstructure, and mechanical performance. Our Greyhound sidesteps these pitfalls by preserving alloy integrity throughout the process, resulting in powder that is highly consistent both chemically and physically.

Much of the skepticism surrounding recycled metals in high-performance manufacturing stems from legitimate concerns about contamination and traceability. In traditional scrap processing, there is often a lack of control over incoming feedstock quality, leading to mixed alloys, unwanted tramp elements, or inconsistent batches. Continuum addresses this challenge through an aggressive front-end sourcing and qualification process. We don’t accept just any scrap. Our sourcing network focuses on high-integrity scrap from known, certified origins — such as retired aerospace components, turbine blades, vanes, housings, and other high-value components originally manufactured to rigorous standards.

Each lot of incoming material undergoes chemical analysis, mechanical cleaning, spectrographic sorting, and batch-level documentation before ever entering our atomization system.

Once the scrap is qualified, it is atomized in our Greyhound M2P plasma atomization platform. This system allows for precise control over particle size distribution, sphericity, flowability, and final chemistry — all critical attributes for downstream processes such as additive manufacturing, metal injection molding, directed energy deposition, and hot isostatic pressing. The result is powder that behaves predictably in the build chamber, reliably delivers full density builds, and consistently meets ASTM-grade specifications for mechanical properties and fatigue performance.

Of course, manufacturing quality alone isn’t enough. For sustainability claims to hold any weight, the process must deliver verifiable environmental benefits. To this end, Continuum partnered with researchers at Oregon State University to conduct a third-party Life Cycle Assessment (LCA) of our nickel powder production process. The results are striking: compared to conventional virgin nickel powder production, our M2P process reduces carbon emissions by up to 99.7%. That represents a fundamental shift in what is possible for decarbonizing metal manufacturing. These reductions are not hypothetical future targets—they are real, documented outcomes already being delivered today.

What makes Continuum’s approach scalable is that our model doesn’t rely on niche or limited scrap sources. High-grade titanium, nickel, and cobalt alloys are widely used across aerospace, energy, defense, and industrial sectors. As components naturally age out of service or manufacturing scrap is generated, these alloys represent a vast, underutilized resource for premium powder production. Rather than seeing scrap as waste, we view it as highly valuable feedstock that can be recaptured and directly reintroduced into the manufacturing supply chain without compromising performance or reliability.

This model also provides a critical benefit for supply chain resilience. The global metal supply chain is increasingly vulnerable to geopolitical instability, raw material shortages, mining disruptions, and unpredictable pricing volatility. By leveraging domestic, certified scrap sources and processing them entirely within our own facilities, Continuum is able to reduce reliance on long-haul international supply chains while offering customers predictable, stable, and secure powder supply.

Ultimately, Continuum Powders exists to prove that sustainability in metal manufacturing isn’t at odds with performance or scale. Through our combination of advanced metallurgy, proprietary atomization technology, and rigorous quality control, we are redefining what’s possible for the production of high-performance metal powders. This isn’t about choosing between sustainability and technical excellence. It’s about building an entirely new framework where both are non-negotiable.

The future of metal manufacturing isn’t a compromise, it’s the full realization that performance and environmental sustainability are two pillars of a new and exciting manufacturing future. At Continuum Powders, we’re showing how a fully circular, high-performance, and scalable manufacturing model is not just possible—it’s already happening.

Contact us today to learn more on how Continuum Powders can help you achieve your advanced manufacturing goals.