In today’s aerospace industry, where material costs are rising and supply chain volatility remains a constant challenge, OEMs are rethinking how they manage their high-value scrap. What once was seen as waste—damaged parts, failed builds, or excess machining stock—is now being recognized as a powerful lever for cost savings, sustainability, and supply chain control.

At Continuum Powders, we’ve developed a model that allows OEMs to unlock the hidden value in their manufacturing and repair operations. By partnering directly with OEM facilities and their authorized repair networks, we turn high-grade aerospace scrap into premium metal powder—ready for reuse in additive manufacturing (AM) and component repair.

A Closed-Loop Model with Real-World Impact

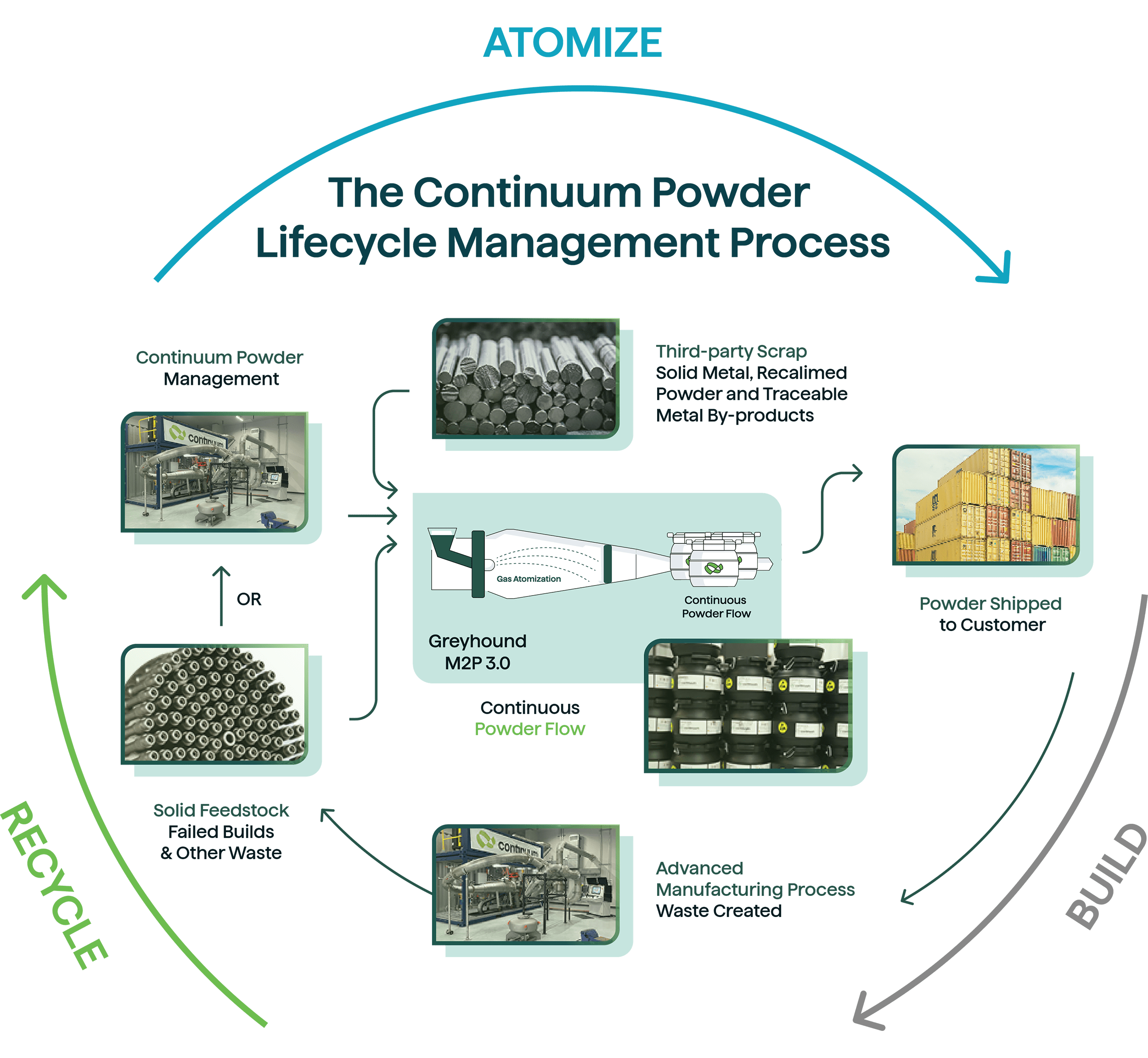

Our Scrap-to-Powder model is simple, scalable, and strategic:

1. OEM scrap is collected directly from manufacturing or repair facilities

This includes machined parts, off-spec components, or excess feedstock made from superalloys such as Mar-M 247, Inconel 718, and titanium variants.

2. Continuum’s proprietary M2P (Melt-to-Powder) technology reprocesses the material into ASTM-grade metal powders

The result: sustainable, high-purity powder that matches the mechanical properties and quality standards required for critical aerospace parts.

3. The powder is supplied to approved repair providers or internal AM teams for certified rebuilds or new part production

In one current engagement, this model is supporting the repair of fan blades for narrow-body commercial aircraft—reducing lead times and lowering material costs while maintaining full material pedigree and traceability.

This loop doesn’t just recover material — it restores strategic value.

Why Scrap Sourcing from OEMs Matters

Sourcing scrap directly from OEM-owned facilities offers clear advantages:

- Full traceability: Knowing exactly where the scrap came from and what it was used for helps meet strict aerospace documentation and compliance standards.

- High-integrity feedstock: OEM manufacturing lines typically produce high-purity materials, making them ideal candidates for reprocessing into new powders.

- Faster approvals: When the powder used in repairs originates from the OEM’s own material, it accelerates qualification and boosts confidence for downstream users.

These benefits have helped Continuum form successful collaborations with top-tier repair networks, and we’re in active discussions with several global OEMs to scale this approach.

Supporting OEM Repair and Advanced Manufacturing Programs

We don’t stop at scrap collection. Continuum Powders is also working with OEMs and their repair networks to:

- Supply recycled powder for certified repair processes, especially for hot-section components like turbine blades and vanes.

- Capture and reuse scrap generated during repair (beyond-economical-repair parts, for example).

- Support internal additive manufacturing programs by replacing virgin powder with our high-quality, low-emission alternative—without compromising performance.

In some cases, OEMs have committed to integrating advanced manufacturing methods for specific engine components. Our powders, built from reclaimed aerospace-grade feedstock, provide a lower-carbon, cost-competitive option that aligns with these forward-looking initiatives.

The Path to Approval—and Advantage

Of course, none of this happens without rigorous quality standards. Continuum’s OptiVantage quality framework ensures:

- In-house analytical testing and certification

- Batch-level documentation

- Closed-loop logistics that preserve material pedigree

Our powders meet—or exceed—the performance of virgin counterparts, and a recent Life Cycle Assessment from Oregon State University shows that our nickel powder production can cut carbon emissions by up to 99.7% compared to traditional methods.

A Strategic Shift for OEMs

In a constrained and carbon-conscious world, OEMs need more than just good powder—they need a smarter materials strategy. Continuum Powders offers that strategy: reclaim valuable alloy scrap, reprocess it into premium AM-ready powder, and reuse it for critical applications—all within a traceable, closed-loop ecosystem.

If your organization is looking to turn excess scrap into certified, sustainable value, we’re ready to help.