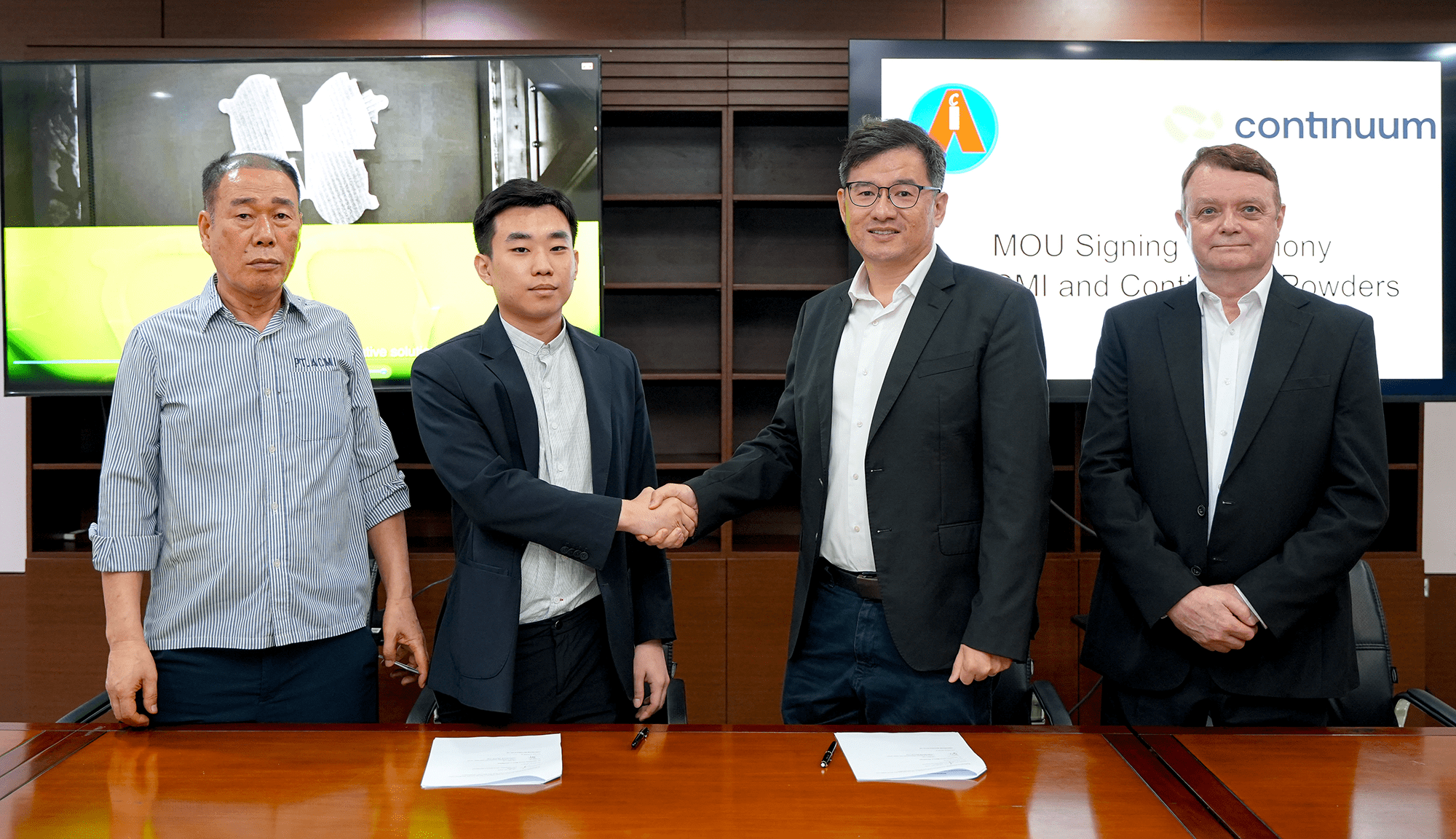

Jakarta, 6 May 2025 – In a landmark development for Southeast Asia’s manufacturing sector, Continuum, a U.S.-based leader in sustainable metal powder production, has entered a strategic Memorandum of Understanding (MoU) with PT. Anugrah Cipta Mould Indonesia (ACMI), Indonesia’s largest contract manufacturer for metal 3D printing and a regional powerhouse in shoemold and precision component manufacturing.

This forward-looking partnership is focused on introducing eco-friendly alloy powders to Indonesia’s industrial ecosystem, while accelerating the onshoring of advanced metal additive manufacturing capabilities. The initiative aims to support growth across multiple high-impact sectors, including shoe Moulds, consumer electronics, energy, automotive, aerospace, and medical devices.

The Continuum and ACMI teams shaking hands after the signing of the agreement.

“Indonesia is becoming a regional manufacturing hub. Our collaboration with ACMI presents an exciting opportunity to integrate sustainability with cutting-edge technology in one of the world’s most promising markets,” said Don Magnuson, Senior Vice President of Sales at Continuum.

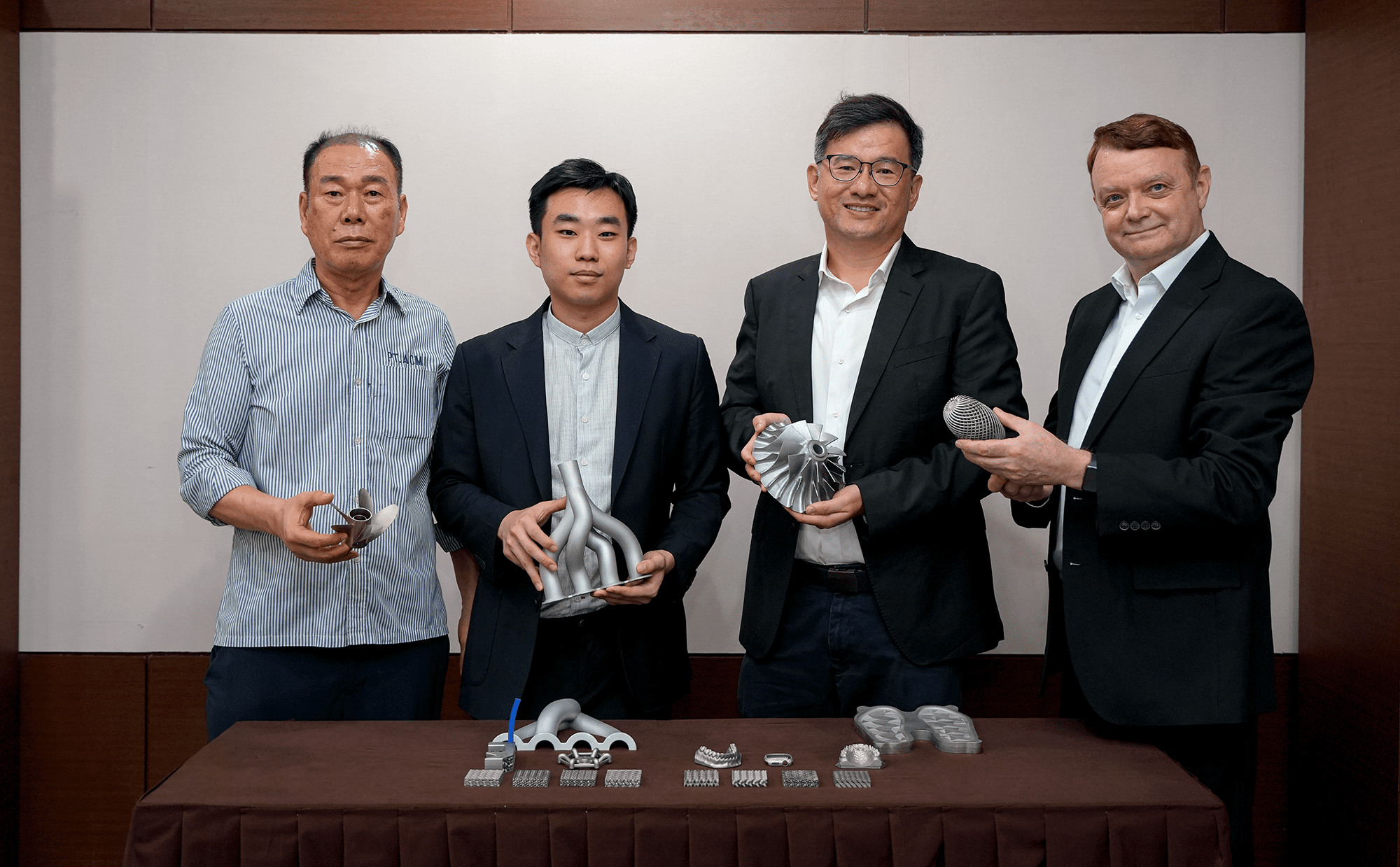

Under the MoU, Continuum and ACMI will jointly qualify up to 8 metric tons of advanced alloy powders for industrial 3D printing applications. This collaboration is expected to substantially reduce carbon emissions, boost local supply chain resilience, and position Indonesia as a regional leader in sustainable manufacturing innovation.

“Our goal is to deliver world-class 3D printing solutions that are optimized for local needs,” added Min Seo Kang, Director at ACMI. “By combining ACMI’s deep manufacturing expertise with Continuum’s green powder technology, we can offer solutions that exceed both industrial performance and environmental responsibility.”

At the heart of this collaboration is Continuum’s patented Greyhound M2P (Melt-to-Powder) Platform — a proprietary cradle-to-cradle process that transforms metal waste directly into high-performance spherical powders in a single step, eliminating the need for traditional melting and atomization while minimizing carbon footprint.

Complementing this is ACMI’s extensive industry experience and its state-of-the-art Additive Manufacturing Center, staffed by over 400 skilled metalworkers and 80 CAD-CAM specialists. ACMI delivers end-to-end services, from part design and Design for Additive Manufacturing (DFAM) optimization to 3D printing and post-processing — serving both local and international clients.

This partnership signifies a milestone in Indonesia’s journey toward cleaner industrial technologies, while delivering immediate value to sectors seeking localized, sustainable, and high-quality additive manufacturing solutions.

About Continuum Powders

Continuum Powders is a global leader in high-performance, sustainable metal powder production. Its patented Melt-to-Powder (M2P) technology transforms alloyed metal waste streams into spherical powders with near-zero carbon emissions. Headquartered in the U.S., Continuum serves manufacturers worldwide in meeting their decarbonization and circular economy goals. www.continuumpowders.com

Media Contact:

Amir Iliaifar

Director of Public Relations

in**@**************rs.com

About PT. Anugrah Cipta Mould Indonesia (ACMI)

ACMI is Indonesia’s foremost metal 3D printing contract manufacturer, with over 30 years of experience in precision metal manufacturing. Serving clients in electronics, tooling, and industrial sectors, ACMI provides comprehensive additive manufacturing solutions from design to final part production — powered by a team of 400 metal professionals and 80 CAD-CAM experts. www.acmigroup.com

Media Contact:

Mr. Min Seo Kang

Director