In metal additive manufacturing, powder is both the fuel and the foundation of production. Yet for many manufacturers, a surprising amount of that valuable material never makes it into a final part. Whether it’s oversize particles, off-spec feedstock, or powder left idle in a hopper after a build, every gram of unused material represents both a lost cost and an untapped opportunity.

At Continuum Powders, we view that opportunity differently. Through Foundry Optimization—a data-driven approach to reclaiming, reusing, and refining metal feedstock—we’re helping manufacturers recover more value from their materials and build a truly circular production model.

The Hidden Cost of Powder Waste

In typical AM workflows, anywhere from 5–20% of powder can go unutilized due to build parameters, particle sizing, or contamination risk. That might not sound like much—until you scale it across hundreds of builds, expensive superalloys, and tight production budgets.

Traditionally, that unused material gets scrapped, stored indefinitely, or sent off for external processing—disrupting production and eroding ROI. As sustainability and cost efficiency become central to every manufacturing decision, this waste stream has emerged as one of the industry’s most overlooked inefficiencies.

A Smarter Approach: Foundry Optimization

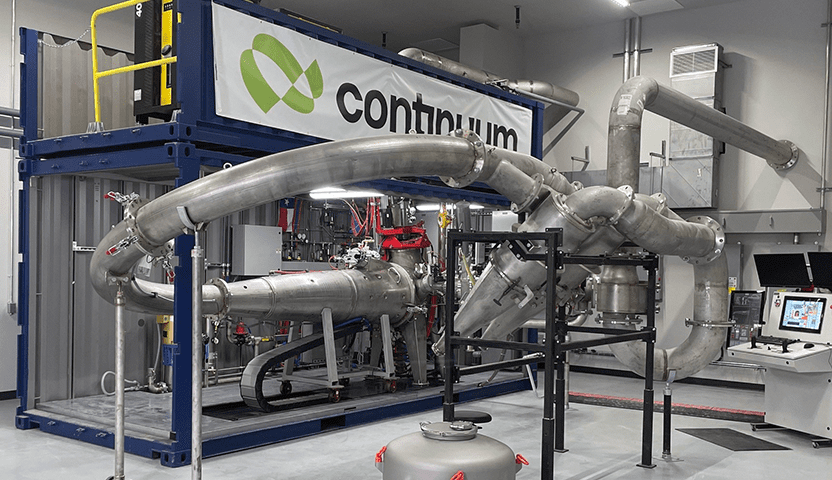

Continuum’s concept of Foundry Optimization bridges this gap. It’s the integration of equipment, analytics, and process expertise to ensure that every metal particle is accounted for—from initial melt to final reuse.

Building on our long-standing capabilities in powder consolidation, Foundry Optimization introduces new tools and workflows that streamline how manufacturers handle their material. At the center of that system is our new Direct Powder Feeder, designed to reclaim unused powder from production environments and return it to the feedstock stream with precision, speed, and full traceability.

Inside the Direct Powder Feeder

The Direct Powder Feeder enables manufacturers to capture unutilized or out-of-spec powder and recondition it for reuse—without losing track of chemistry, cleanliness, or performance. By maintaining strict control over powder flow and documentation, it ensures that reclaimed material meets the same rigorous quality standards as virgin feedstock.

The result is an optimized material loop that reduces waste, shortens turnaround time, and eliminates unnecessary purchasing cycles—all while preserving the integrity of every batch.

Rebuilding Value Across the Supply Chain

For manufacturers, the implications are significant. Foundry Optimization allows organizations to:

- Reduce material costs by reclaiming high-value powders instead of discarding them.

- Strengthen supply continuity by maintaining internal access to usable powder.

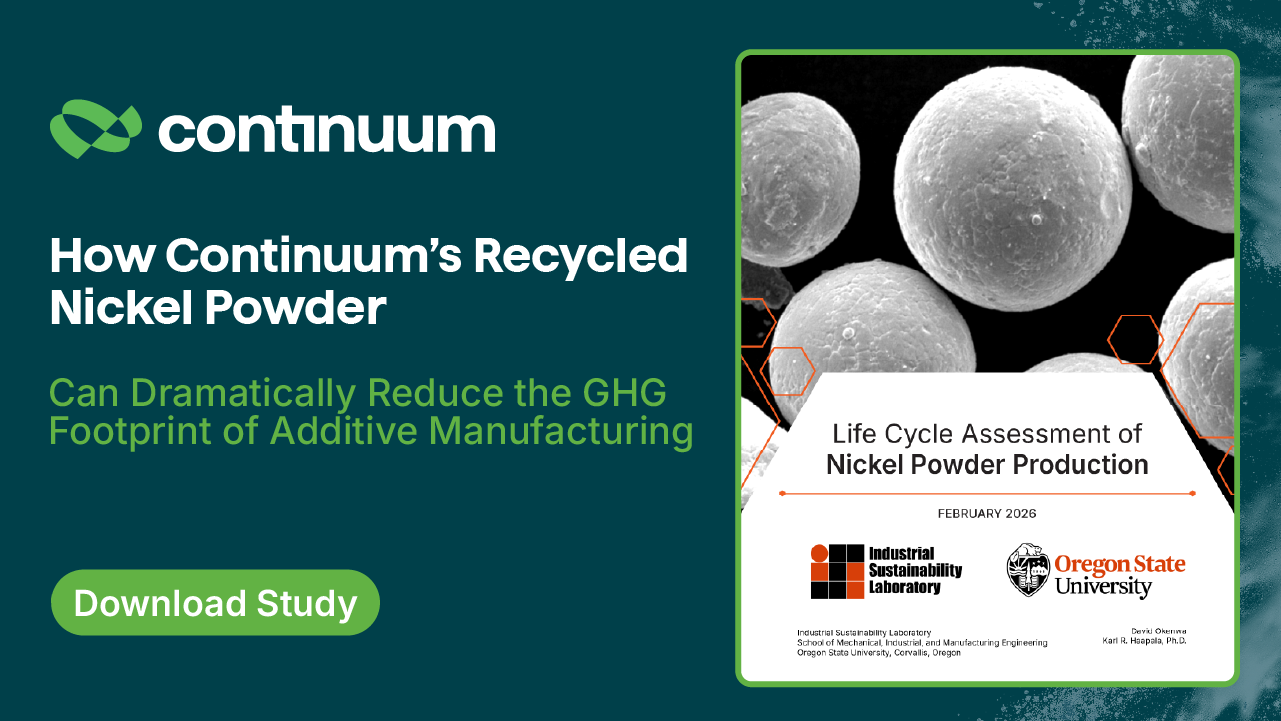

- Accelerate sustainability goals by minimizing scrap and reducing reliance on virgin metal inputs.

- Improve operational agility by keeping feedstock closer to the point of use.

By rethinking how powder is managed and reused, Continuum is empowering manufacturers to take control of their material lifecycle—and to view feedstock not as a consumable, but as a renewable asset.

Looking Ahead

Foundry Optimization represents a critical step toward fully circular manufacturing—where material efficiency, sustainability, and performance coexist in the same workflow.