Suppressor components face extreme operational demands—thermal cycling, corrosive gas exposure, and high-frequency fatigue loading. Additive manufacturing (AM) enables innovative geometries and material savings, but successful suppressor builds depend on powder characteristics that go beyond basic alloy selection.

This guide outlines the metallurgical and powder-level considerations that drive suppressor performance, and how Continuum Powders supports defense and tactical manufacturers with materials engineered for real-world stressors.

Operational Stresses That Define Material Requirements

Suppressor AM parts must tolerate:

- Sustained temperatures above 600°C during rapid-fire and full-auto use

- Chemical degradation from combustion residues and corrosive gases

- Repeated thermal cycling, which introduces fatigue and crack initiation

- Tight tolerance demands for complex baffles and flow pathways

These stresses demand more than a high-performance alloy—they require high-integrity powder.

Alloy Landscape: Ni718, Titanium Grades 5 & 23, and Ni7208

Inconel 718 (Ni718): Remains a leading choice due to its high-temperature strength, corrosion resistance, and stable metallurgical response in LPBF systems.

Ti64 Grades 5 & 23: Offers a compelling mix of heat tolerance, fatigue resistance, and lightweight advantages. Increasingly used in tactical suppressors where mass reduction is critical.

Ni7208: Known for exceptional thermal fatigue resistance, especially in sustained full-auto or military applications. Though not offered by Continuum Powders, its relevance in suppressor design reinforces our deep industry expertise.

Key Powder Characteristics for Suppressor Manufacturing

Even the right alloy will fail if powder properties are inconsistent. The following powder characteristics determine part success:

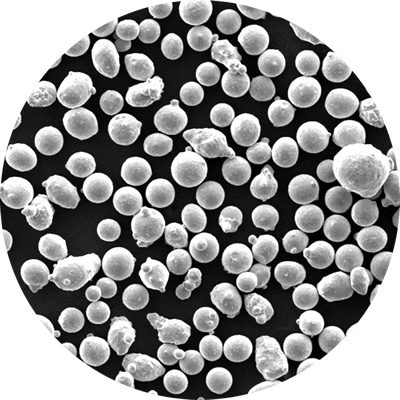

– Gas-Atomized Spherical Morphology: Promotes flowability and minimizes recoater interference

– Tight PSD Control (15–45 µm typical): Supports dimensional accuracy and surface finish

– Low Oxygen, Nitrogen, and Carbon: Interstitials significantly impact fatigue life and crack resistance

– Traceability and Lot Consistency: Required for defense-grade parts and qualification processes

Continuum Powders: Engineered for Lifecycle Performance

We don’t just supply powder—we engineer material solutions. Continuum Powders provides:

- Tailored PSDs for suppressor geometries and AM systems

- In-house analytical chemistry labs for batch-level purity assurance

- Gas-atomized, flowable powders for high-reliability builds

- Sustainable U.S. scrap sourcing and full traceability from input to output

From prototype to production, we help materials engineers build suppressors that meet lifecycle reliability requirements.

Let’s discuss how to optimize your suppressor powder inputs.

Contact us for technical consultation or request a sample today.

OptiPowder Ni718 – 140X