In advanced manufacturing, high-performance metal powders are the essential foundation for mission-critical applications. Whether producing aerospace turbine components, defense systems, or medical implants, manufacturers depend on powders that deliver not only mechanical strength but also strict consistency, traceability, and sustainability.

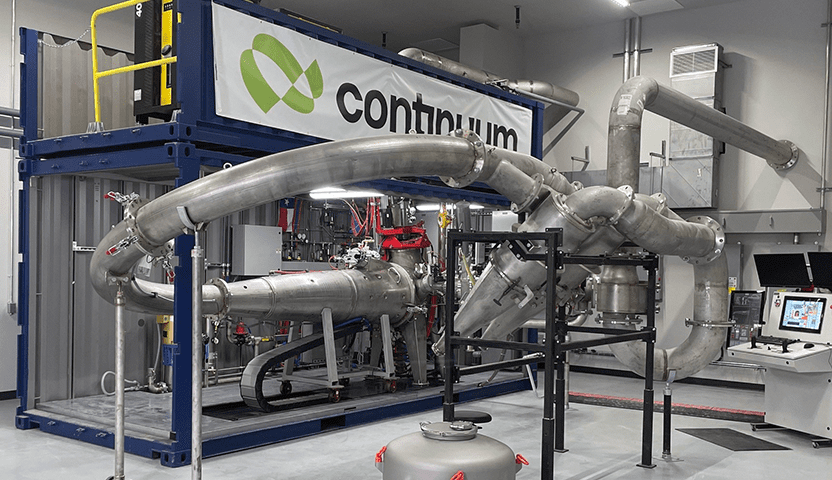

At Continuum Powders, delivering that performance begins with one critical technology: our Greyhound Melt-to-Powder (M2P) system.

Unlike conventional powder production methods that rely heavily on virgin raw materials and multiple remelting stages, M2P represents a fundamental shift in how premium powders are produced. This system allows Continuum to reclaim certified aerospace- and energy-grade scrap and convert it directly into ASTM-grade metal powder, all in a single controlled step.

In this article, we’ll break down the science behind the Greyhound M2P system, why it represents such a major leap forward, and how it helps Continuum deliver both uncompromising quality and transformative sustainability benefits.

The Traditional Challenge: Why Conventional Powder Production Falls Short

Before we dive into M2P, it’s important to understand the problems it solves. Traditional metal powder production generally follows a resource-heavy pathway: ore extraction, multiple refining stages, primary melting, and final atomization. Even when recycled material is used, conventional recycling typically requires several high-temperature remelting steps to refine the scrap, which not only consumes significant energy but also introduces opportunities for oxidation, alloy degradation, and compositional drift.

Each remelt cycle potentially compromises alloy integrity and reduces material efficiency, making these traditional methods difficult to scale sustainably, particularly for highly reactive or composition-sensitive alloys like Inconel 718, Haynes 282, titanium Ti-6Al-4V, or nickel-based superalloys.

Additive manufacturing demands powders with exacting particle size distributions, clean chemistries, excellent sphericity, and highly repeatable flow behavior. Achieving those characteristics with conventional multi-step remelting approaches often results in wide particle size distributions and higher yield losses, which further reduce production efficiency.

Enter Greyhound M2P: One Step, Fully Controlled

The Greyhound M2P platform at the center of Continuum’s process takes a completely different approach. Rather than subjecting reclaimed scrap to repeated remelting and reprocessing cycles, M2P converts solid feedstock directly into atomized powder — preserving the material’s alloy integrity while minimizing processing steps, energy input, and total emissions.

At its core, the M2P process is built around a DC plasma heat source. Plasma is an extremely hot, ionized gas capable of generating the thermal energy required to rapidly melt metal feedstock, often exceeding temperatures of 10,000°C at the plasma arc core. In this ultra-high-temperature environment, even high-melting-point superalloys are quickly and fully melted without relying on multiple remelting steps.

This fully molten stream is then atomized into fine powder using a carefully controlled high-pressure gas jet. The molten metal breaks up into droplets which rapidly solidify into powder particles as they cool and descend through the atomization chamber. The parameters of both the plasma arc and atomizing gas are finely tuned to control droplet formation, particle size, and cooling rates.

Continuum Powders’ Greyhound Melt-to-Powder Foundry

The Key Technical Advantages of M2P

What sets M2P apart is how tightly controlled every variable of the process is from start to finish. This delivers several technical benefits that directly translate to powder quality:

- Narrow Particle Size Distribution: Because M2P controls droplet formation at the plasma atomization stage, it naturally produces a more concentrated PSD, minimizing oversized or undersized particles and maximizing usable powder yield.

- Spherical Morphology: M2P-generated powder exhibits highly spherical particles, improving flowability, layer uniformity, and packing density—critical attributes for consistent recoating and full-density builds in additive manufacturing.

- Smooth Surfaces and Low Satellite Formation: The rapid solidification in the inert environment reduces the likelihood of satellites or irregular shapes, which can compromise powder flow and print quality.

- Reduced Oxygen and Hydrogen Pickup: Operating in a tightly sealed, inert atmosphere allows M2P to minimize contamination, oxidation, or gas absorption—preserving alloy purity critical for fatigue-sensitive parts.

- Single-Step Conversion: Eliminating multiple remelting stages reduces the risk of compositional drift or phase changes that can occur during prolonged thermal cycling.

Sustainability by Design

While the technical advantages are significant, the real breakthrough with M2P is how it enables Continuum’s circular manufacturing model to scale while ensuring the quality needed of advanced manufacturing applications.

Because M2P can process certified scrap directly, Continuum eliminates the need to mine, refine, and ship virgin metals from the ground up. Aerospace-grade nickel, titanium, and cobalt alloys that would traditionally enter a downgrade recycling loop — or be discarded altogether — are instead recovered, reprocessed, and reintroduced into high-value manufacturing.

This approach isn’t just a marketing claim. A third-party Life Cycle Assessment (LCA) conducted by researchers at Oregon State University demonstrated that Continuum’s nickel powder production process reduces carbon emissions by up to 99.7% compared to conventional virgin metal powder production. That’s not incremental improvement. It’s a complete rethinking of the metal manufacturing supply chain.

Built for Advanced Manufacturing at Scale

The powders produced through M2P are specifically engineered for next-generation manufacturing methods including:

- Laser Powder Bed Fusion (LPBF)

- Directed Energy Deposition (DED)

- Metal Injection Molding (MIM)

- Binder Jetting (BJT)

- Hot Isostatic Pressing (HIP)

Because M2P delivers highly consistent powder characteristics, manufacturers using these processes benefit from more predictable builds, higher part reliability, faster qualification, and less powder waste while aligning with increasingly strict ESG goals and regulatory pressures.

The Science is Proven. The Model is Scalable. The Future is Here.

At Continuum Powders, we view our M2P platform not just as a manufacturing technology but as the foundation of an entirely new production model—one where sustainability and quality are fully compatible, not competing priorities.

By combining advanced plasma physics, controlled gas atomization, and rigorous front-end material qualification, Continuum is delivering metal powders that meet the world’s most demanding technical standards—while dramatically lowering the environmental cost of producing them.

In an industry facing mounting pressure to decarbonize, secure supply chains, and scale reliably, Continuum’s Melt-to-Powder system is proving that sustainable metal production is no longer aspirational — it’s operational.

Contact us today to learn more on how Continuum Powders can help you achieve your advanced manufacturing goals.