New study confirms Continuum Powders’ technology cuts carbon emissions by up to 99.7%

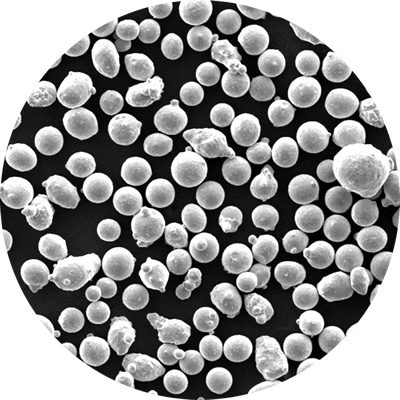

Revolutionizing Nickel Powder, Sustainably

Continuum Powders has achieved a significant milestone in sustainable manufacturing. An independent Life Cycle Assessment (LCA) conducted by Oregon State University’s Industrial Sustainability Laboratory confirms that Continuum’s proprietary Melt-to-Powder (M2P) technology reduces carbon emissions by up to 99.7% compared to traditional nickel powder production methods. Download an overview to the right, and get the full study here:

Key Highlights:

- Innovative Process: Unlike conventional methods that rely on energy-intensive virgin nickel, Continuum’s M2P technology directly converts 100% recycled nickel scrap into high-performance powders without the need for remelting or chemical adjustments.

- Environmental Impact: The LCA compared three production scenarios. The conventional approach, using 100% virgin nickel, contributed to 96% of the global warming potential (GWP) in the production process. In contrast, Continuum’s method, utilizing 100% recycled nickel and green energy sources, achieved a 99.7% reduction in carbon emissions.

- Industry Implications: This advancement supports major decarbonization goals in sectors like aerospace, defense, and energy, where high-performance powders are critical. By adopting Continuum’s sustainable approach, manufacturers can significantly cut emissions, enhance supply chain resilience, and reduce dependency on scarce raw materials.

Download the Full Study