OptiPowder Ni718

High-Performance Nickel Superalloy for Demanding Applications

Download Data Sheet

Ni718 is a nickel-chromium-molybdenum-niobium precipitation-hardened superalloy known for its excellent machinability before heat treatment and outstanding strength after heat treatment. Ni718 offers sustained high-temperature strength, stress rupture strength, cryogenic stability, and oxidation resistance, making it an ideal choice for advanced manufacturing in demanding environments.

Continuum Powders is proud to offer OptiPowder Ni718, produced using our proprietary M2P Gas Atomization System— a plasma-based process that transforms reclaimed metal revert streams into high-quality spherical powder in a single step. This environmentally responsible process, powered by green energy, significantly reduces the carbon footprint of our powder production, while ensuring consistent quality and excellent flowability.

| Printed Properties (at room temperature) | ||||

| Printed On | Concept Laser | EOS 290 | ||

| Direction | OptiPowder Ni718 | OptiPowder Ni718 | ASTM 3055 | |

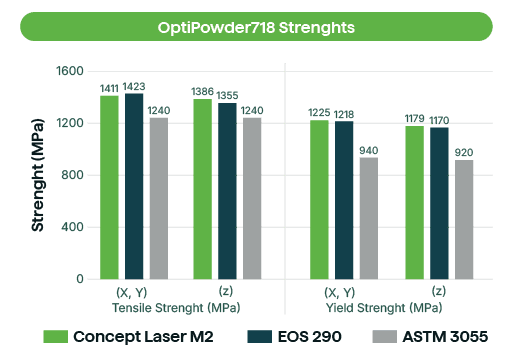

| Tensile Strength (MPa) | (XY) | 1411 | 1423 | 1240 |

| (Z) | 1386 | 1356 | 1240 | |

| Yield Strength (MPa) | (XY) | 1225 | 1218 | 940 |

| (Z) | 1179 | 1170 | 920 | |

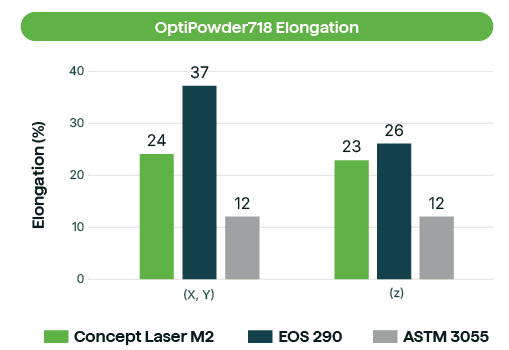

| Elongation (%) | (XY) | 24 | 37 | 12 |

| (Z) | 23 | 26 | 12 | |

| Conforms to AMS7006 and ASTM F3055 |

| Nominal Composition (wt%) | |||

| Ni | 50.0-55.0 | Si (max) | 0.35 |

| Cr | 17.0-21.0 | Ti | 0.65-1.15 |

| Mo | 2.80-3.30 | Al | 0.20-0.80 |

| Fe | Balance | C (max) | 0.08 |

| Nb+Ta | 4.75-5.50 | P (max) | 0.015 |

| Co (max) | 1.00 | S (max) | 0.015 |

| Mn (max) | 0.50 | B (max) | 0.006 |

| Typical Physical Properties | |

| Apparent Density | >4.0 g/cc |

| Tapped Density | >5.0 g/cc |

| Hall Flow Time | <20 s/50g |

OptiPowder Ni718 is engineered for advanced manufacturing and is particularly suited for applications requiring high-temperature resistance, with the ability to withstand temperatures up to 1200°C (2200°F). This makes it ideal for components used in aerospace, power generation, and automotive industries. Its high strength, fatigue resistance, and creep resistance make it perfect for stress-critical components in demanding environments.

In the aerospace sector, Ni718 is used for turbine blades, rocket motors, and combustion chambers, providing the strength and oxidation resistance needed to endure extreme conditions. In the oil and gas sector, Ni718 is used for components exposed to corrosive environments, ensuring long-term durability. For industrial gas turbines, Ni718 maintains both reliability and efficiency, preserving mechanical integrity and performance under extreme operating temperatures. Additionally, Ni718 is widely utilized in fuel cell technologies, including Solid Oxide Fuel Cells (SOFCs), due to its stability in both high and low temperature environments.

OptiPowder Ni718 supports various AM processes, including:

- Laser Powder Bed Fusion (LPBF): Ideal for producing complex parts with high accuracy and mechanical properties.

- Electron Beam Melting (EBM): Suitable for creating large, complex parts with excellent mechanical properties.

- Binder Jetting: A cost-effective AM process for producing larger parts with lower density and porosity.

Continuum Powders offers OptiPowder Ni718 in various particle size distributions (PSD) to meet your specific manufacturing needs. Representative properties shown here are for laser powder-bed fusion (LPBF) powder PSD.

OptiPowder718 Elongation

OptiPowder718 Strengths