In the world of aerospace, precision, reliability, and traceability are non-negotiable. So, when the word “recycled” enters the conversation, particularly when discussing metal powders for additive manufacturing, many engineers and procurement leaders react with understandable skepticism.

After all, this is an industry built on meticulous standards. The notion of introducing materials made from scrap into critical applications can sound counterintuitive—if not risky.

But here’s the reality: recycled metals are already deeply embedded in aerospace manufacturing. And not just in non-critical components. Aerospace-grade alloys derived from scrap are currently flying in airframes, engine housings, and structural assemblies around the world.

This isn’t about cutting corners—it’s about applying modern technology to capture, refine, and reuse valuable material with full quality control. With the right process, recycled feedstock can yield equal or better performance than virgin materials. The key lies in how it’s processed—and that’s where Continuum Powders comes in.

The Boeing and Alcoa Closed-Loop Recycling Program

One of the most prominent examples of recycled metals in aerospace comes from a collaboration between Boeing and Alcoa (now Howmet Aerospace). In a closed-loop program launched in 2013, the two companies committed to recycling more than 8 million pounds of high-grade aluminum scrap annually, primarily from 2XXX and 7XXX series alloys used in aircraft structures.

These scrap materials were cleaned, sorted, and reprocessed into new aerospace-grade stock, then reintegrated into Boeing’s supply chain. The closed-loop model dramatically reduced waste and ensured full traceability—from raw material to the functional part. This program proved a critical point: when managed with rigorous standards, aerospace alloys can be recycled to the virgin alloy state and meet the same performance requirements.

The Rolls-Royce Revert Program

Rolls-Royce has also long championed the value of reclaimed metals through its Revert program—a highly controlled recycling system that processes and reuses more than 95% of manufacturing waste and used parts across its global operations. This includes superalloys from critical engine components such as turbine blades and discs, which are collected, sorted, and reprocessed back into new certified materials for aerospace applications. As Rolls-Royce explains:

“Revert allows Rolls-Royce to maintain the high quality and integrity required for aerospace components, while significantly reducing the demand for newly mined raw materials and the environmental impact of its supply chain.”

Both programs demonstrate that with rigorous process control, scrap-derived metals can meet even the most exacting aerospace standards.

The Challenge with Powders: Purity and Predictability

When it comes to metal powder, especially for additive manufacturing, concerns about “recycled” input focus largely on two things: contamination risk and inconsistent chemistry. For the powders in AM, traditionally “recycled” powder means that the powder that has been in the print chamber but was not the part of a part produced. Such powder is re-sieved and directed back into the powder hooper either using external or integrated powder sieving system. Such recycled powder can be contaminated with the debris from the printing process. Continuum’s OptiVantage system has a different approach: We remelt and atomize the alloys. In short, Continuum produces virgin alloy metal powders using recycled metal alloys. This differentiates the meaning of “recycling”.

These are valid concerns. Improperly handled scrap can introduce variability or trace elements that degrade performance. But Continuum Powders addresses these challenges head-on through a tightly controlled OptiVantage process designed to deliver ASTM-grade, application-ready powders from high-integrity reclaimed feedstock.

The Continuum Approach: Scrap to Spec Without the Risk

Continuum’s solution starts with strategically sourced scrap—not just any recycled metal, but material originally certified to mee the chemistry requirements for the intended application applications. These include components like turnings, waste powder, turbine blades, vanes, and housings made from high-value alloys such as Inconel 718, M247 and titanium Ti-6Al-4V.

Once collected, the material undergoes rigorous pre-treatment, including:

- Mechanical/chemical cleaning to remove contaminants

- Alloy classification

- Batch-level chemistry and contaminants inspection and tagging for traceability

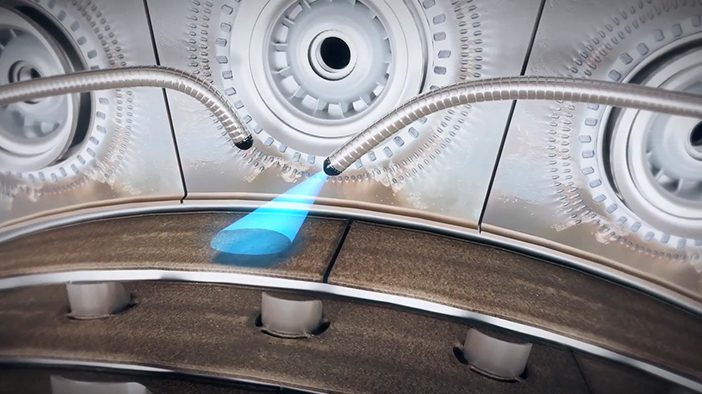

The prepped reclaimed metal alloy is then processed using Continuum’s proprietary Greyhound M2P (Melt-to-Powder) system—a plasma-based atomization platform that melts and atomizes the input feedstock into powder in a single, tightly controlled step. Continuum’s cold hearth refining technology further ensures to trap any tiny heavy contaminants present in the reclaimed metal alloy.

Unlike traditional recycling methods that may involve multiple remelting stages, which may evaporate some elements in the alloy and/or induce oxidation, the M2P process maintains chemical integrity, spherical particle morphology, and flow characteristics, all of which are critical for powder for AM.

The Results: Verified Performance and Traceable Quality

Continuum Powders are manufactured under the OptiVantage quality framework, which includes:

- Comprehensive QA protocols, including chemical, flowability, and PSD testing

- Onsite analytical chemistry labs for real-time data collection

- Lot-specific documentation to ensure traceability and repeatability

- End-to-end logistics and batch control to prevent cross-contamination or loss of pedigree

The result is a virgin metal alloy powder that performs on par with or better than traditional alternatives—in terms of performance

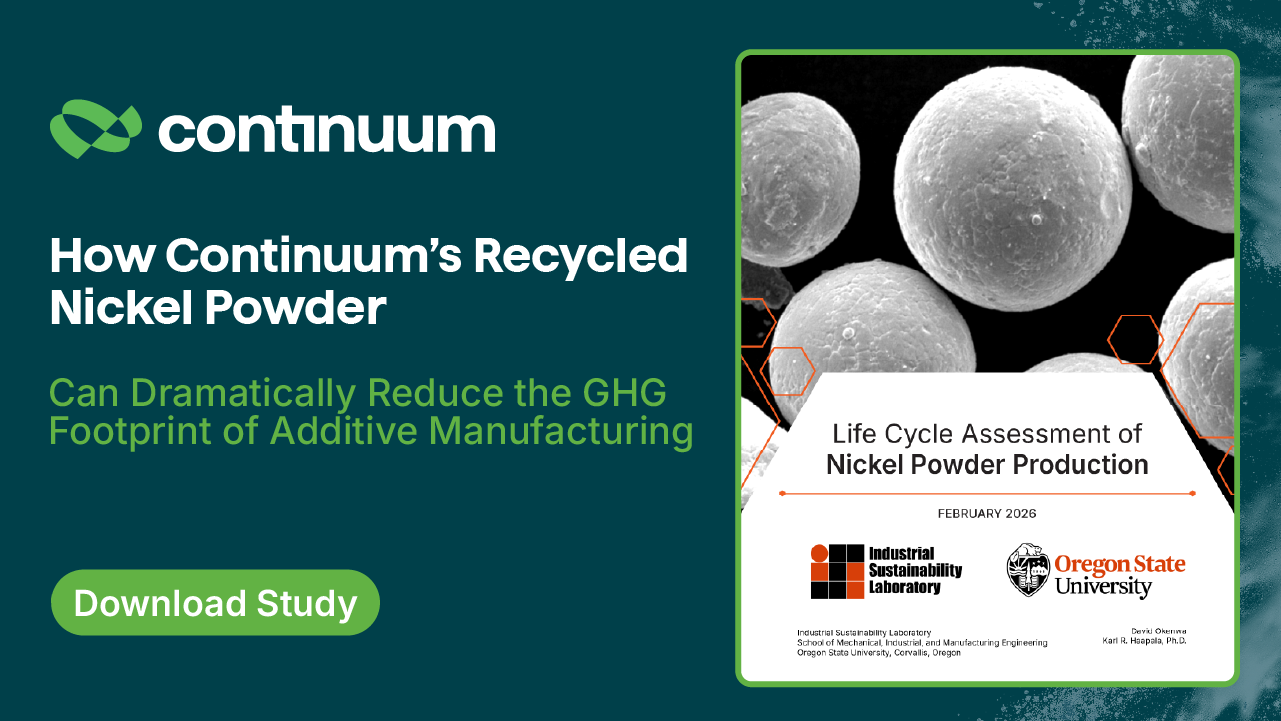

Further, the multiple process steps in traditional refining and powder manufacturing collects a lot of carbon footprint when the powder is ready for use, while Continuum’s 1 step process reduces the carbon footprint drastically. And this isn’t just theory. A Life Cycle Assessment (LCA) conducted by researchers at Oregon State University found that Continuum’s recycled nickel powder production process using M2P reduces carbon emissions by up to 99.7% compared to traditional nickel powder manufacturing.

This means manufacturers can achieve their performance specs while also advancing ESG goals and reducing exposure to volatile raw material markets.