When engineers talk about metal powders for additive manufacturing, particle size distribution (PSD) often comes up early in the conversation. Yet despite how frequently it’s referenced, PSD is still widely misunderstood — or oversimplified to a single number that doesn’t tell the full story.

In reality, PSD plays a critical role in how powders behave during printing, how consistently parts are produced, and how predictable downstream processes like sintering or post-processing will be. Understanding what PSD actually represents, and how it should be selected for different additive manufacturing processes, is essential for achieving repeatable results.

This article breaks down what PSD is, how it’s measured, and how to think about selecting the right distribution based on your application and process — not just a line item on a datasheet.

PSD Explained

Particle size distribution describes the range and proportion of particle sizes present in a powder batch. Rather than being made up of particles that are all the same size, metal powders consist of a spectrum of sizes, from very fine particles to larger ones.

PSD is typically reported using percentile values based on powder volume:

- D10: 10% of the powder sample is smaller than this size

- D50: The median particle size

- D90: 90% of the powder sample is smaller than this size

Together, these values help describe not just the average size of particles, but how wide or narrow the overall distribution is. These percentiles summarize PSDs regardless of distribution shape. They are widely used for lot-to-lot control, but they do not uniquely define distribution shape.

A narrow PSD means most particles fall within a tight range. A broader PSD includes a wider mix of fine and coarse particles. Neither approach is inherently “better”, the right choice depends heavily on the additive manufacturing process and the performance requirements of the application.

Why PSD Matters in Additive Manufacturing

PSD influences how a powder behaves at nearly every stage of the AM workflow.

From a processing standpoint, particle size affects powder flowability, layer spreading, packing density, and how evenly powder beds or binder layers are formed. From a part-quality perspective, PSD can influence density, surface finish, dimensional accuracy, and the consistency of mechanical properties.

PSD also plays a role in process stability. Powders with poorly controlled distributions can contribute to variability from build to build, even when machine parameters remain unchanged. For manufacturers looking to move from prototyping to production, that variability becomes a real risk.

Narrow vs. Broad Distributions: Understanding the Tradeoffs

One common misconception is that tighter particle size distributions are always preferable. In practice, both narrow and broad distributions have advantages and limitations depending on the process and end-use requirements.

A narrow PSD typically offers more predictable flow behavior and layer thickness, along with reduced particle segregation. This can be beneficial for processes that rely on precise powder spreading and consistent layer formation. However, very narrow distributions may reduce packing density, leaving more void space between particles.

A broader—or intentionally engineered—PSD can improve packing density by allowing smaller particles to fill the gaps between larger ones. This can be advantageous for processes where green density or sintering behavior is critical. At the same time, excessive fines can negatively impact flowability or increase the risk of dusting and segregation.

The goal is not to maximize or minimize particle size variation, but to select a distribution that supports the requirements of the specific process, alloy, and part geometry.

In practice, this often means offering multiple PSD options for the same alloy to support different manufacturing pathways. Continuum Powders supplies a broad portfolio of metal powder particle size distributions tailored to specific applications and processes. For a proven, widely used alloy like Ni718, which is qualified across several advanced manufacturing workflows, Continuum offers PSDs spanning the full range—from fine cuts such as 0–15 µm and 0–45 µm, to mid-range fractions like 15–45 µm and coarser distributions including 45–106 µm, as well as material optimized for HIP applications. This flexibility allows customers to select a PSD that aligns with their printing method, post-processing route, and performance targets.

Across alloys and processes, Continuum routinely partners with customers to tune PSD alongside flowability and packing behavior, ensuring powders perform predictably through spreading, printing, and sintering. This collaborative, application-driven approach has helped reduce iteration time and support production readiness and qualification milestones for advanced manufacturing platforms, including metal binder jetting.

PSD Considerations by Additive Manufacturing Process

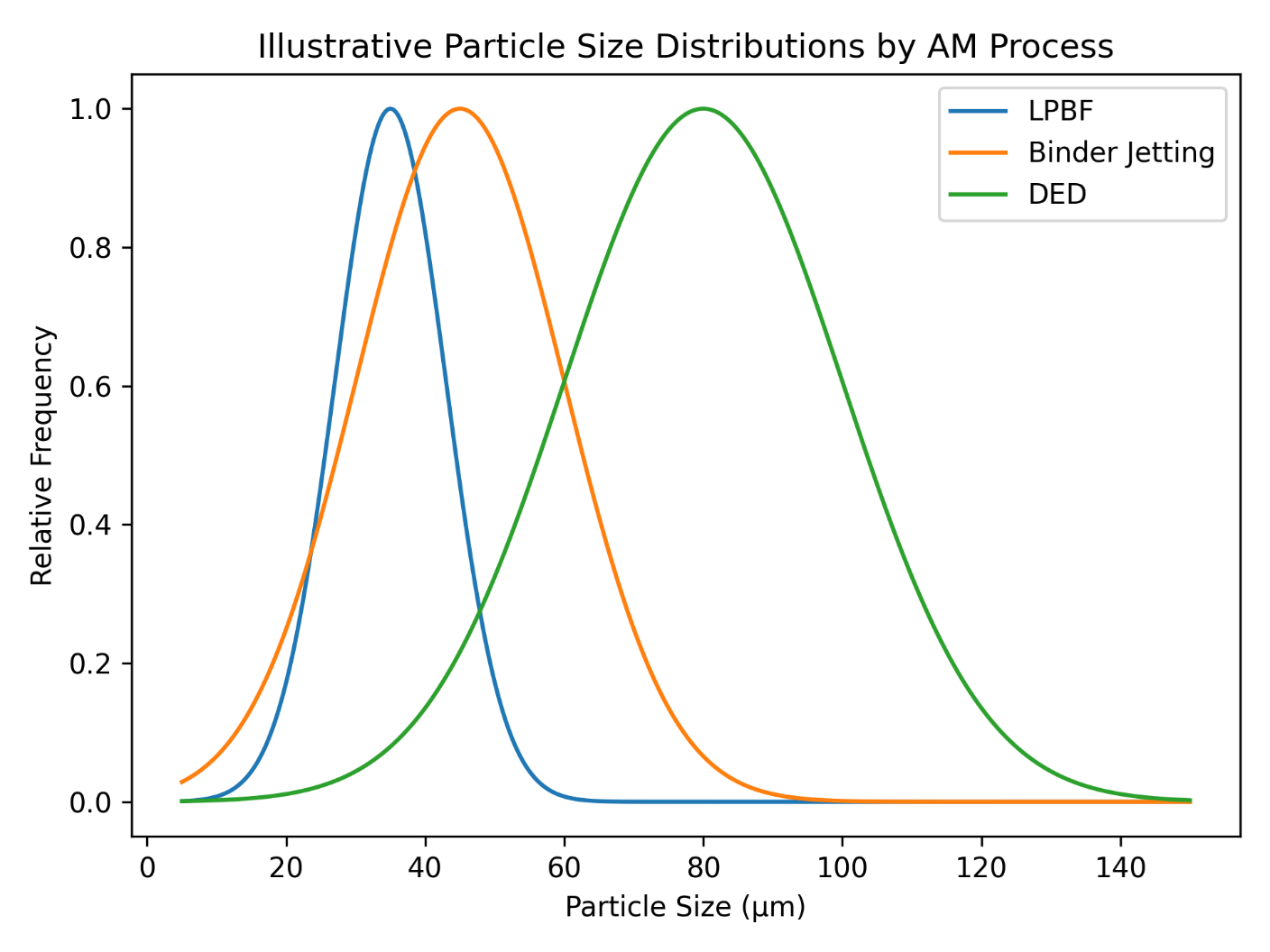

While there is no universal PSD that works for every application, certain trends apply across major AM technologies.

For laser powder bed fusion (LPBF), PSDs are typically tighter and selected to support the target layer thickness and stable spreading. Flowability remains critical, but excessive coarse particles can disrupt layer uniformity.

In binder jetting, packing density and uniform powder spreading are often higher priorities.

Slightly finer distributions may be advantageous, particularly when sintering behavior and dimensional control are key considerations. Alternative distribution types for binder jetting powders include bimodal distributions, which can significantly increase the packing density of the powder while minimizing shrinkage.

For directed energy deposition (DED) processes, coarser powders are commonly used. Here, consistent feeding and stable powder flow into the melt pool matter more than achieving extremely fine resolution.

These distinctions highlight why copying PSD specifications from one process to another can lead to unexpected performance issues.

How PSD Is Measured — and Why Method Matters

PSD is most commonly measured using laser diffraction techniques, though sieving and image analysis may also be used depending on particle size range and application.

Measurement method matters because different techniques can yield different results for the same powder, particularly when dealing with irregular shapes or agglomerates. Understanding how PSD data was generated is just as important as the numbers themselves.

When comparing powders, it’s important to ensure that PSD data is produced using consistent methods and clearly documented procedures.

PSD Is Only One Part of the Powder System

While PSD is a critical parameter, it should never be evaluated in isolation. Particle shape, surface condition, apparent density, tapped density, flowability, and chemistry all interact with PSD to determine real-world powder performance.

Two powders with identical D10, D50, and D90 values may behave very differently if their morphology, surface chemistry, or distribution shape differs. This is why successful powder selection requires a holistic view of material characteristics rather than relying on a single metric.

Choosing the Right PSD: A Practical Mindset

Rather than asking, “What is the best PSD?”, a more productive question is, “What PSD best supports my process, part geometry, and production goals?”

Answering that question requires understanding how powder properties interact with your specific AM technology, build parameters, and quality requirements. It also benefits from working with powder suppliers who can help tailor distributions based on application needs rather than offering one-size-fits-all solutions.

As additive manufacturing continues to mature, PSD selection will increasingly be viewed not as a fixed specification, but as a design variable — one that can be optimized alongside process parameters to achieve better outcomes.