Metal Waste to High-Performance Powders

Continuum Powders and Knust-Godwin

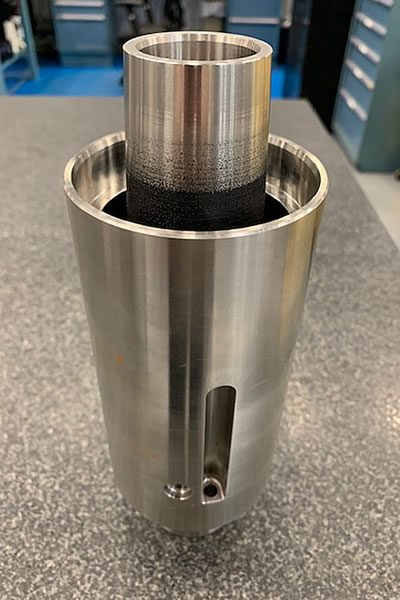

A finished oil and gas component, printed from Optipowder Ni718, with a specialized interior coating designed to reduce wear and extend operational life. Image courtesy of Knust-Godwin.

See how Knust-Godwin LLC transformed Ni718 recycling with Continuums’ innovative Melt-to-Powder process! This case study showcases how a major oil & gas company reduced waste, cut costs, & achieved ASTM-grade quality with reclaimed metal powders. Watch now to discover the future of sustainable manufacturing!

What Makes Us Different

U.S.-based, green-powered production

in California and Texas

Recycled feedstock

that reduces emissions and global dependencies

Engineered for consistency

across LPBF, Binder Jetting, MIM, HIP, and DED

Custom PSDs and chemistries

to match platform-specific specs

Certified compliant

for aerospace, medical, and industrial applications