In the world of aerospace maintenance, repair, and overhaul (MRO), performance and reliability are everything. Customers depend on fast turnaround times, tight quality control, and proven results—especially when working with mission-critical components like turbine blades, vanes, and housings. But with global supply chains under strain and raw material costs rising, many MROs are asking: how can we deliver more value without compromising standards?

At Continuum Powders, we’ve built a closed-loop model specifically designed to help aerospace repair shops and MROs reduce costs, ensure part traceability, and access high-quality metal powders—without relying on unstable virgin material supply chains.

A Better Way to Source Powder: From Scrap to Spec

Traditional metal powder comes from energy-intensive virgin metal production, subject to price fluctuations and long lead times. But what if the material you need is already sitting in your shop—or your customer’s?

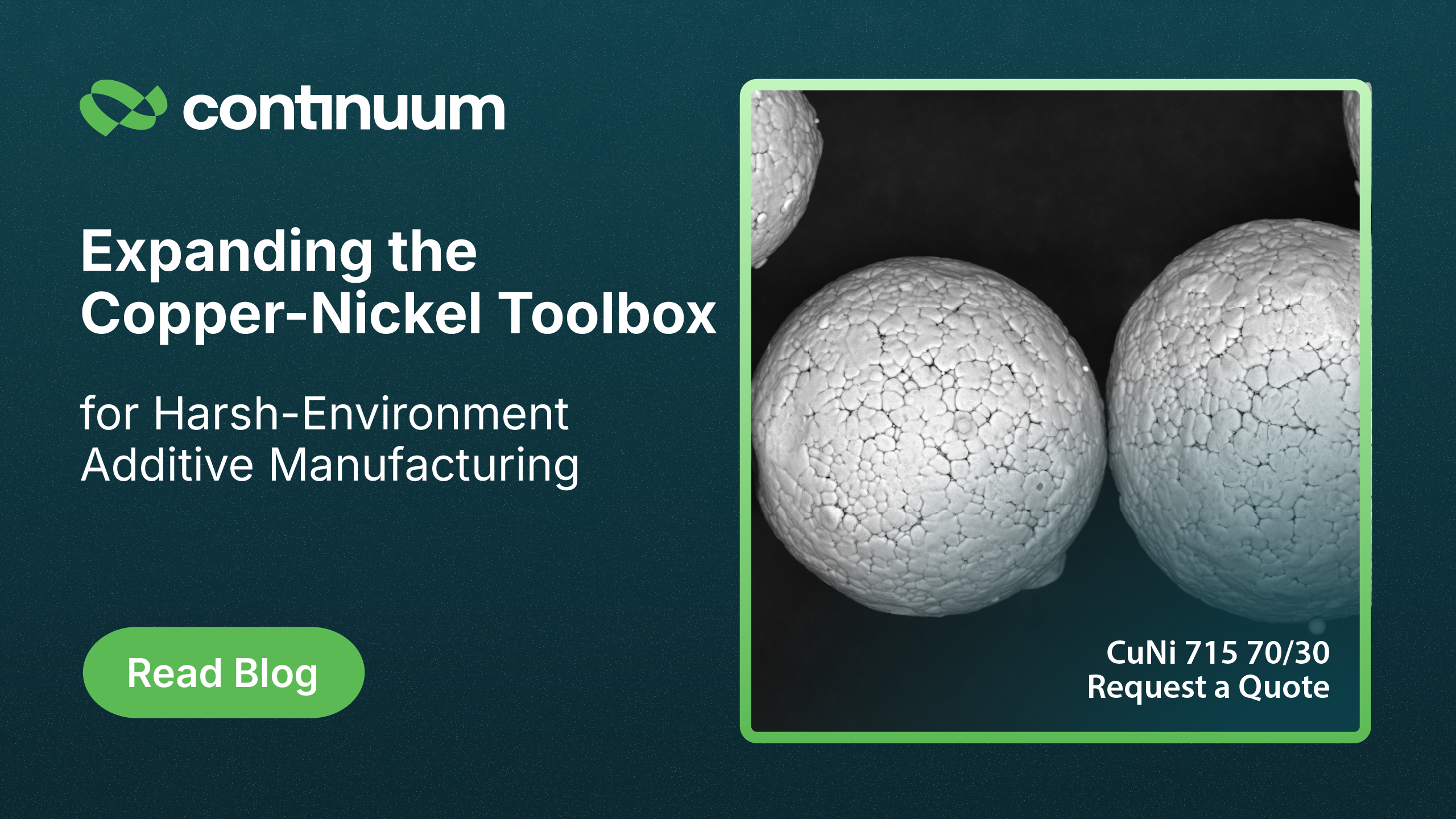

Continuum’s process begins with high-integrity scrap from OEM-certified components—think fan blades, housings, or failed builds. That scrap is collected, cleaned, and processed through our Greyhound M2P (Melt-to-Powder) system. In a single-step, plasma-based atomization process, we turn that material into application-ready metal powder with outstanding consistency, spherical morphology, and excellent flowability.

What This Means for MROs

For repair providers, this isn’t just recycling, it’s an opportunity to:

- Secure a stable supply of certified powder for repair operations, including hot-section components

- Lower material costs by reclaiming valuable alloys like M247, Inconel 718, or titanium Ti-6Al-4V

- Reduce lead times by avoiding long procurement cycles for virgin powder

- Build credibility with OEMs by using material that can be traced directly back to their own manufacturing lines

We’ve seen growing interest among top-tier aerospace repair partners who are seeking qualified powders for fan blade repairs and turbine component rebuilds. In many cases, sourcing scrap from the OEM and converting it into powder used in repairs becomes a value proposition everyone can align behind—OEM, MRO, and end customer.

Built for Certainty: The OptiVantage Framework

MROs operate in one of the most tightly regulated sectors in manufacturing. That’s why every Continuum powder is produced under our OptiVantage Quality Framework, which includes:

- In-house analytical testing for chemistry, flowability, and particle-size distribution

- Batch-level documentation and traceability

- Strict contamination controls and dedicated logistics

- ASTM-grade output specifically qualified for aerospace and energy applications

The result: powder that matches or exceeds the performance of virgin material, while aligning with sustainability goals and helping repair providers stay agile and competitive.

A Real-World Example of Strategic Repair

Let’s say you’re repairing a turbine blade for a narrow-body commercial aircraft. With Continuum, you can:

- Source scrap directly from the OEM or from failed repairs.

- Have it converted into high-purity powder that meets repair specs.

- Use that powder to complete a certified rebuild—faster, with full traceability.

You reduce your material waste, lower your costs, and offer your customers a solution that’s both technically sound and environmentally responsible.

The Bottom Line

Continuum Powders gives MROs the ability to take control of their material supply, meet performance requirements, and reduce dependence on global raw material markets. Whether you’re looking to speed up part repairs, lower cost-per-repair, or align with ESG goals, reclaiming and reusing aerospace-grade alloys is no longer a compromise, it’s a competitive edge.

Let’s talk about how we can help you build smarter repairs, with smarter powders.