Unlocking M247 for Binder Jet AM: From Casting Alloy to Printable Superalloy – ebook

Bridging the Gap Between Legacy Superalloys and Next-Generation Production

Download our eBook to see how Continuum’s OptiPowder™ M247/M247LC moves a casting-bound alloy into scalable binder-jet production—pairing high-temperature performance with circular, U.S.-made powder supply.

Why this matters

- A proven alloy, now printable. M247 is renowned for strength, creep resistance, and oxidation stability near 1,000 °C, traditionally limited to casting.

- Casting constraints are real. Domestic superalloy casting capacity has fallen by ~60% over the past decade, driving long lead times and design compromises. Binder jetting offers speed, scalability, and geometry freedom.

- Sustainable feedstock, engineered for AM. OptiPowder is produced via Continuum’s plasma-based Greyhound Melt-to-Powder (M2P) process using 100% reclaimed aerospace-grade feedstock, tight PSD, excellent sphericity, and flow for predictable builds.Why this matters

Inside the eBook

- Material overview: What makes M247 and low-carbon M247LC suitable for hot-section aerospace/energy components.

- Manufacturing challenge: The supply-chain impact of shrinking casting capacity and why an additive path is strategic.

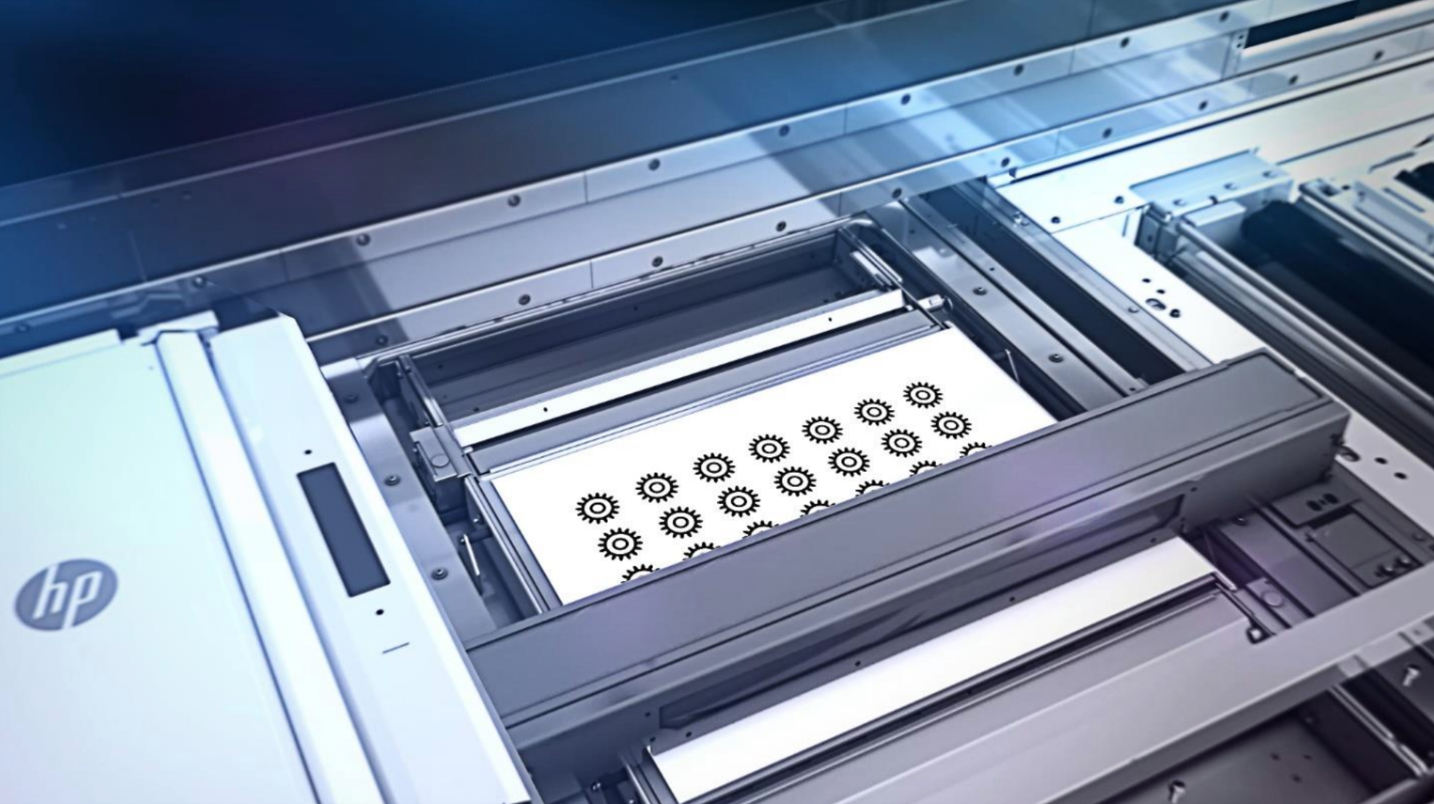

- The breakthrough: Binder-jet qualification progress with partners (HP AM Solutions, AmPd Labs, Tecnalia) and the path to reliable densification and repeatable properties.

- Powder innovation: AM-designed powder attributes (flowability, narrow PSDs) and platform flexibility (MBJ, LPBF, HIP, MIM, DED, EBM).

- Industry impact: Faster iteration, lower cost of innovation, stronger domestic supply, and sustainable sourcing via reclaimed feedstock.

- What’s next: From ‘proven alloy’ to ‘future standard’ for high-temp AM parts.

Download Today

Images courtesy of HP AM Solutions